Slag Pot

| Weight | 10~85 t |

| Material | ZG230-450 plus RE etc. |

| Customizable | Yes |

Slag pot,also called slag ladle,pour ladle or steel ladle,which is important device in steel making. It is a load-bearing device to collect molten or solid slag generated during metallurgical or chemical processes. It is a bowl-shaped container with lifting lugs at both sides. A grilling is installed inside the pot, under at least 300mm of the upper surface and divides the inner pot into some pieces. The slag pot that purchased by metallurgical enterprises generally is made by traditional cast process with long manufacturing cycle, short service life, and great scrapped quantity. Xinxiang Great Wall Steel Casting Co., Ltd, through continuous technical innovation in produce process, the slag pot has more advantages such as short cast period, long service life and strong resistance to deformation.

Simulation for slag pot liquid solidification process Moulding site of slag pot

Pouring of slag pot on site The heating treatment of slag pot on site

Product Features:

- Greatly reducing the manufacturing period by means of constant technological innovation;

- Cost-effectively, Massive users: Our slag pot is the common choice of many large world-renowned steel enterprises from Mittal, Tata, Taiwan and so on, such as Taiwan Zhong Hua Iron& Steel Company.

- Long service life better than the traditional casting slag pot: Great-wall slag pot's usage frequency can reach 2000 times, its first maintenance can be done 2~3 months later than similar products from other manufacturers, and it enjoys a longer service life.

- Outstanding durability: According to operating conditions, Chaeng slag pot engineers adopt suitable material, customize and optimize the casting technology. That will make the slag pot have the performances of excellent high temperature mechanical properties, good thermal cracking resistance, stable manufacturing process and so on.

- Excellent casting processes: Chaeng performs digital simulation of casting process by means of CAE before pouring, to achieve the optimization of slag pot casting process.

- Good appearance,Strong resistance to deformation: Chaeng is quite skillful at shot blasting and sand blasting to ensure the good appearance of slag pot and improve paint adhesion.

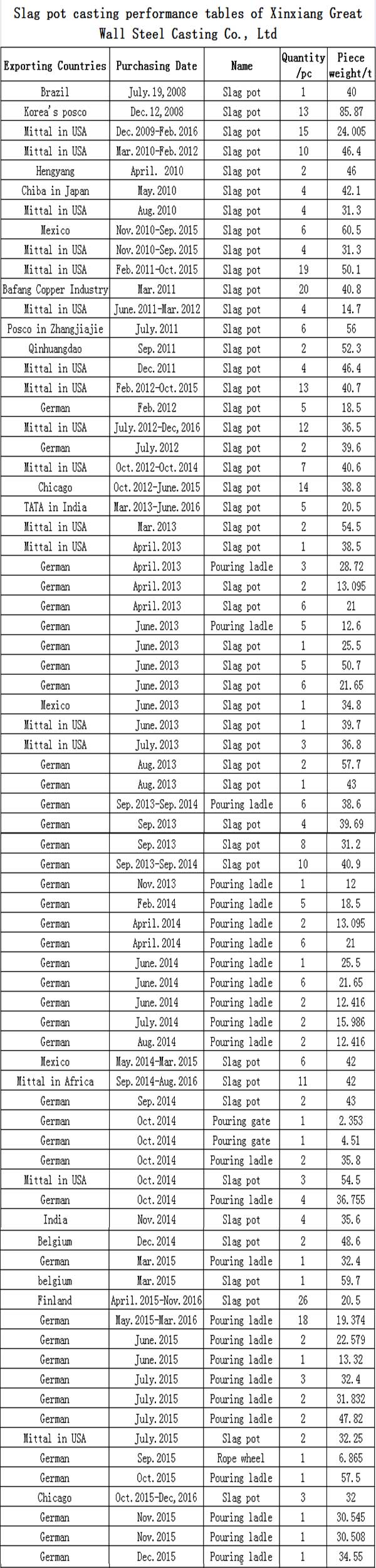

All kinds of slag pots are exported to all over the world

Casting Steel Manufacturing Process:

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

Cases:

- World Steel-Mittal Group ording ording 65t slag pot for iron & steel smelting.

- China Anshan Iron and Steel Group co., LTD ording our 58t slag ladle for mechanical processing.

- Baosteel Group Corporation ording 62t pour ladle for steel casting manufacturing.

On July 18, 2008, the Great Wall steel casting signed the first contract of slag pot, under the situation of financial crisis and shrinking market, on the same year on December 12 we signed 13 pcs of slag pot with South Korea's posco, since 2008 we have signed the contract of more than 50 types of slag pot, and produce 287 pieces of casting process, "they" are exported to countries around the world: the United States Mittal, Germany, Italy, India's TATA steel company, Japan Chiba, Canada, Taiwan. in slag pot manufacturing technology, we have accumulated rich experience in turnover of slag pot liquid container of the black metal, non-ferrous metal, the lead smelting, slag pot has composed the personalized brand new chapter for Great Will casting steel… …

Our service:

Pre-sales Planning

Be a good staff and assistant of the customer, and make sure every investment get high return.

- Provide suggestions for the customer about steel castings production according to customer demand or drawing size.

-

Design the manufacturing process of casting parts according to customers' special requirements.

-

Engineering technicians make site planning and design for customers on site.

After-sales Service

The end of sales is not the end of our service. Continuous and reliable service will save your worries.

- Send professional after-sales people on site to assist our customer in installation and debugging.

- Provide train for operational staff.

- Our casting warranty is one year, during which maintenance is free.

- If any problem comes up, please contact with us at any time. We will send professional technician on-site service.

Application:

- Blast Furnace

- High Temperature Melting Equipment

- Steel mill

- Metallurgy industry

- Mechanical processing industry