Cement Rotary Kiln

| Application | Cement Plant, Quicklime Plant |

| Capacity | 300-5000 t/d |

| Motor Power | 160-630 kW |

| Weight | 252-841 tons |

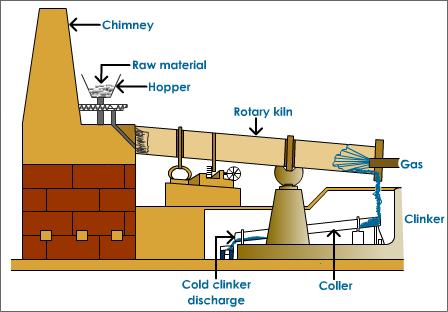

Cement rotary kilns are used for the pyroprocessing stage of manufacture of Portland and other types of hydraulic cement, in which calcium carbonate reacts with silica-bearing minerals to form a mixture of calcium silicates. Over a billion tonnes of cement are made per year, and cement rotary kilns are the heart of this production process: their capacity usually define the capacity of the cement plant.

Our rotary kiln is a cylindrical vessel, inclined slightly to the horizontal. The material is fed into the upper end of the cylinder. As the kiln rotates, the materials gradually move towards the lower end, and they may go a certain amount of stirring and mixing. Hot gases go through the rotary kiln, in the same direction as the process material, but usually in the opposite direction. The hot gases may be generated in an external furnace, or may be generated by a flame inside the kiln. They are repetitively scattered in the air so that they are in full contact with the hot air, the material is dried gradually.

Supporting device: advanced shaft structure, automatic temperature measuring device and electrical heating.

Gears: single or double. Control the rotating speed by buncher, DE machine and frequency variable motor. Be reliable, energy-saving, and efficient.

Cylinder tire bolster: lower bolster has three types: fixed, zoom and floating. The structure is simple, replacement is convenient and won’t hurt cylinder.

Sealing equipment: there are many kinds for choice according to kiln models, including air cylinder edge sealing, spring edge sealing, and graphite block sealing and combination for above. The sealing effect is very good.

Catch wheel: including two kinds mechanical wheel and hydraulic pressure.

| Model (m) | Volume (m³) | Output (t/d) | Temperature (℃) | Heat Consumption (KJ/kgCaCo3) |

|---|---|---|---|---|

| φ2.5*40 | 142 | 150 | 1350/1250 | 5300/5000 |

| φ2.8*42 | 190 | 200 | 1350/1250 | 5300/5000 |

| φ3*46 | 235 | 250 | 1350/1250 | 5300/5000 |

| φ3.2*50 | 292 | 300 | 1350/1250 | 5300/5000 |

| φ3.5*54 | 390 | 350 | 1350 | 5225 |

| φ3.6*56 | 430 | 400 | 1350 | 5225 |

| φ3.8*58 | 505 | 500 | 1350 | 5100 |

|

φ4*60 φ4.2*50 |

575/548 | 600 | 1350 | 5100 |

| φ4.3*58 | 670 | 750 | 1350 | 4810 |

| φ4.3*64 | 738 | 800 | 1350 | 4810 |

| φ4.8*68 | 1005 | 1000 | 1350 | 4810 |

Pre-sales Service:

The wide product range enables us to provide our customers with stand-alone machines or complete processing plants. Based on our customers’ request and budget, our experts make efficient, reliable solutions. Following customers’ order we produce strictly, what’s more, before placing the order every customer has the chance to visit XinXiang Great Wall (Chaeng) working machines or complete plant in the site.

To ease the trip for every visitor to China, in particular the first-time visitor, we provide FOR FREE all relevant visitor-friendly services including invitation letter preparation, hotel reservation, airport pick-up, incity transportation, and sightseeing guide, et

After-sales Service:

Experienced technicians guidance is available on the phone, and on the internet. One or more engineers will be dispatched to the quarry site to help install the customers’ plants. Necessary training about machine daily maintenance to local workers is provided also.

After-Sales department is made of well-trained employees and installation engineers, the installation engineers are special and professional members of XinXiang Great Wall (Chaeng), they are now strategically located home and abroad, working for our customers.

Appliaction:

Cement rotary kiln, which is mainly used for calcinating cement clinker, is the main equipment of the new dry type cement production line. This equipment is mainly composed of cylinder, supporting device, supporting device with catch wheel, transmission device, lubrication device, mobile kiln head and sealing device at the end of the kiln