Steel Slag Grinding Plant

| Annual Output | 200,000-1,500,000 tons |

| Main Equipment | GRMS Steel slag vertical mill |

| Grinding Material | Steel Slag , Water Slag , Blast Furnace Slag |

| Matching equipment | Feed Belt +Vibrating screen+slag vertical mill+hot blast stove+dust collector+warehouse |

The product of the CHAENG ( Great Wall Machinery ) production steel slag vertical roller mill is the equipment to grind Ground Granulated Blast furnace Slag into small particles . steel slag(fineness:4200-4500cm2/g) produced by vertical roller mills are being used to substitute clinker in conventional cement manufacturing as well as to partially replace OPC for ready-mixed concrete production, for which the percentage of GGBS usage is typically at 10-15% and 20-25% respectively.

Steel slag is the waste residue in the process of steel making, including converter slag and electric furnace slag, approximately takes 15-20 percent of crude steel capacity , It occupies a large proportion of industrial waste.--Steel slag is the waste residue in the process of steel making, including converter slag and electric furnace slag, approximately taking 15-20 percent of crude steel capacity. It occupies a large proportion of industrial waste.

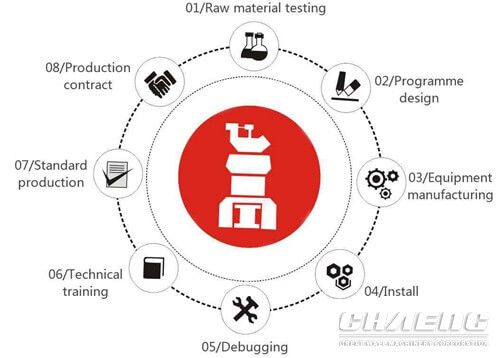

CHAENG can undertake 20 tons --1.5 million tons of Blast furnace slag/Steel slag/Nickel slag/Manganese slag powder production EPC projects.We can provide raw material testing , engineering design,equipment manufacturing,install,debugging,technical training,standard production,production contract and "turnkey" service.

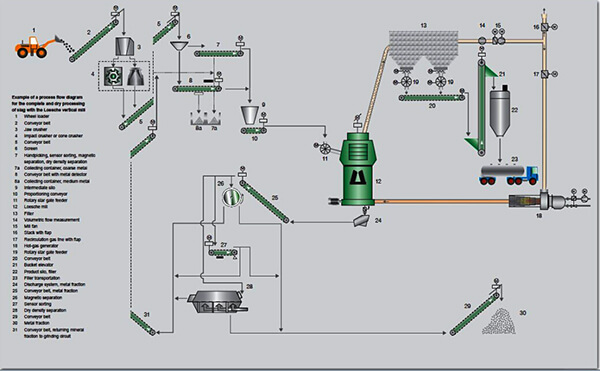

Process Description

Forklift will transfer the steel slag from the slag pile to the weighting silo.

During the transportation, the steel slag will be magnetized and sieved to remove the iron parts.The pre-processed slag then will be fed to the vertical mill by the elevator for grinding.

After grinding, the steel slag will be classified and dried by the hot air generator.

The required steel slag powder then will be collected by the dust collector and transferred to the final product ware house by air delivery chute and elevator.

Technical Parameters

According to the survey, 600,000 tons of steel slag powder production line is becoming the mainstream market of steel slag production line capacity, and technical parameters of the full set of equipment of annual CHAENG leading 600,000 tons of slag powder production line is:

| Scale | 600,000 tons of steel slag grinding production line equipment parameters | |

|---|---|---|

| Vertical roller mill | model | GRMS46.41 |

| Production Capacity | 100 t/h | |

| Feeding Size | ≤5mm | |

| Fineness | ≥ 420 m²/kg | |

| main motor power | 1600kw | |

| Rod mill | model | φ3.0 × 4.5m rod mill |

| Production Capacity | 90-95 t/h | |

| Feeding Size | ≤ 30mm | |

| The particle size | ≤ 5mm | |

| main motor power | 630 Kw | |

| Fan dust collector system | model | CCLF 4 × 11 |

| Air volume | 400,000 m³h | |

| Wind | 400,000 m³h | |

| Full pressure | 8100pa | |

| Motor Power | 1250 kw | |

| Coal-fired fluidized bed furnace | Heating capacity | 1600 × 104 kcal/h |

| fuel | coal | |

Project Case

In addition to 600,000 tons of steel slag production line, we can also provide the full set of equipment and its technical parameters of annual output of 300,000 tons of steel slag powder production line, annual output of 450,000 tons of steel slag powder production line and annual output of 1 million tons of steel slag powder production line. Please consult online service or leave a message, and our manager will contact with you as soon as possible.

Product advantages

1. The specific surface area of slag powder finished product is higher than 450㎡ / kg, which has high activity.

The specific surface area of CHAENG vertical mill production of steel powder is 450 to 500 ㎡ / kg, which has higher activity with ideal energy consumption indicators at this time.

2. The power consumption of production line system is in 40KWh / t

High ball mill energy consumption has been a big problems for many cement companies for a long time, while the new vertical mill equipment has become the most internationally recognized technology leader in energy saving grinding equipment, and stand-alone energy consumption can be reduced more than 30%!

3. The dust emission concentration is 22mg / m³

Slag vertical mill set conveying, grinding, drying, powder selecting into an organic whole and work in a closed and negative pressure environment. The vibrating screen frame and feeding frame is equipped with monitoring equipment. The entire line dust emission concentration is 22mg / m³, far below the national standard of 30mg / m³.

4. High iron selection rate to increase additional economic benefits

Iron content of slag generally ranging from 1% to 3% , CHAENG’s optimize the iron selected process of vertical mill and grinding system to increase multi-channel Separators in the feeding system, greatly increasing the amount of metallic iron elect improved system comprehensive economic environmental benefits.

5. The shortest delivery period at the market

CHAENG mainframe-added capabilities and large steel castings manufacturing capacity, can guarantee the quality of products under the premise of the slag vertical mill delivery guarantee in 4-6 months, the entire production line construction period is shortened to 6-8 months.

Investment return

Guangdong,China— a large steel company, 600,000 tons of steel slag comprehensive utilization of resources projects Case Analysis

Project Overview:

A company from Guangdong, after the process of hot stew, crushing and screening, magnetic separation, coarse grinding, all kinds of broken steel slag into the annual output 600,000 tons of steel slag comprehensive utilization of resources and environmental protection engineering production line slag heap storage shed,Then by screening, magnetic separation, pre-pink coarse grinding, broadband magnetic separator selected iron and steel slag particles selected processes 6,000 tons of iron powder after crushing the slag into the slag vertical mill drying, grinding. Finely ground slag powder by the high concentration bag filter to collect into steel slag storage library, the library through the end of Sinotrans bulk loading systems.

Investment calculation:

According to the local and neighboring markets that:

Integrated steel slag powder is priced at $ 22 / ton, it is put into the annual average revenue $13326242;

As the project was elected in 6000 tons of steel slag particles, iron powder, according to the price of $ 137 / ton, the annual income is $759763;

The final total annual revenue: 60,0000 tons *$22 +6000 tons *$137=$14040419

service support

To ensure that the entire project of customers is completed smoothly, CHAENG pioneered the industry's first value-added solutions of "1 vertical mill, eight services" , and from project approval to the final production, the Great Wall machinery will provide full guidance.