Rotary dryer

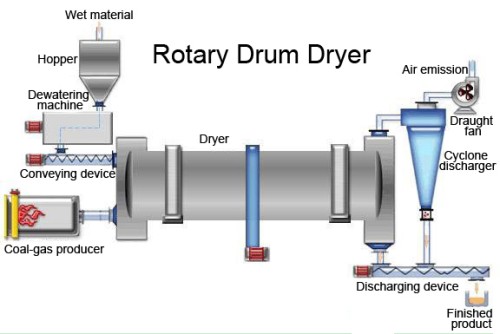

The rotary dryer is a type of industrial dryer employed to reduce or minimize the liquid moisture content of the material it is handling by bringing it into direct contact with a heated gas. Rotary dryer is suitable to dry metallic and nonmetallic mineral, clay in cement industrial and coal slime in coal mine, etc. Rotary dryer can be widely used to dry various materials, and it is simple to be operated.

Great wall rotary dryer is made up of a large, rotating cylindrical tube, usually supported by concrete columns or steel beams. The dryer slopes slightly so that the discharge end is lower than the material feed end in order to convey the material through the dryer under gravity

Material to be dried enters the dryer, and as the dryer rotates, the material is lifted up by a series of internal fins lining the inner wall of the dryer. When the material gets high enough to roll back off the fins, it falls back down to the bottom of the dryer, passing through the hot gas stream as it falls, and then the material dried.

(1) The internal adopts assembled structure, which has improved the accuracy of the equipment. It is easy to transport and stall.

(2) According to the characteristics of different fertilizers, we have arranged the second granulation zone reasonably so as to improve the granulation effect.

(3) Adopts assembled hoist board so as to exchange heat fully and lower the energy consumption.

(4) Temperature induction monitor, uniform vibration and airproof setting improve performance and productivity efficiently.

(5) The assorted combustion furnace is a type of energy-efficient and equipped withgreenhouse.

Rotary dryer is mainly used for the drying and dehydration of various materials for the manufacture of compound fertilizer

| Type (mm) | Rotation Speed (r/min) | Input Temperature (℃) | MotorPower (KW) | Output (t/h) | Weight (T) |

|---|---|---|---|---|---|

| φ600*6000 | 3-8 | ≤700 | 3 | 0.5-1.5 | 2.9 |

| φ800*8000 | 3-8 | ≤700 | 4 | 0.8-2.0 | 3.5 |

| φ800*10000 | 3-8 | ≤700 | 4 | 0.8-2.5 | 4.5 |

| φ1000*10000 | 3-8 | ≤700 | 5.5 | 1.0-3.5 | 5.6 |

| φ1200*10000 | 3-8 | ≤700 | 7.5 | 1.8-5 | 14.5 |

| φ1200*12000 | 3-8 | ≤700 | 11 | 2-6 | 14.8 |

| φ1500*12000 | 2-6 | ≤800 | 15 | 3.5-9 | 17.8 |

| φ1800*12000 | 2-6 | ≤800 | 18 | 5-12 | 25 |

| φ2200*12000 | 1.5-6 | ≤800 | 18.5 | 6-15 | 33 |

| φ2200*18000 | 1.5-6 | ≤800 | 22 | 10-18 | 53.8 |

| φ2200*20000 | 1.5-6 | ≤800 | 30 | 12-20 | 56 |

| φ2400*20000 | 1.5-5 | ≤800 | 37 | 18-30 | 60 |

| φ2800*15000 | 1.5-5 | ≤800 | 40 | 20-35 | 72.5 |

| φ2800*18000 | 1.5-5 | ≤800 | 40 | 25-35 | 75 |

| φ3000*20000 | 1.5-5 | ≤800 | 55 | 28-40 | 78 |

| φ3000*25000 | 1.5-5 | ≤800 | 75 | 32-45 | 104.9 |

Pre-sales Service:

The wide product range enables us to provide our customers with stand-alone machines or complete processing plants. Based on our customers’ request and budget, our experts make efficient, reliable solutions. Following customers’ order we produce strictly, what’s more, before placing the order every customer has the chance to visit XinXiang Great Wall (Chaeng) working machines or complete plant in the site.

To ease the trip for every visitor to China, in particular the first-time visitor, we provide FOR FREE all relevant visitor-friendly services including invitation letter preparation, hotel reservation, airport pick-up, incity transportation, and sightseeing guide, et

After-sales Service:

Experienced technicians guidance is available on the phone, and on the internet. One or more engineers will be dispatched to the quarry site to help install the customers’ plants. Necessary training about machine daily maintenance to local workers is provided also.

After-Sales department is made of well-trained employees and installation engineers, the installation engineers are special and professional members of XinXiang Great Wall (Chaeng), they are now strategically located home and abroad, working for our customers.

Application:

Rotary dryer is suitable to dry metallic and nonmetallic mineral, clay in cement industrial and coal slime in coal mine,etc. Rotary dryer can be widely used to dry various mine materials.