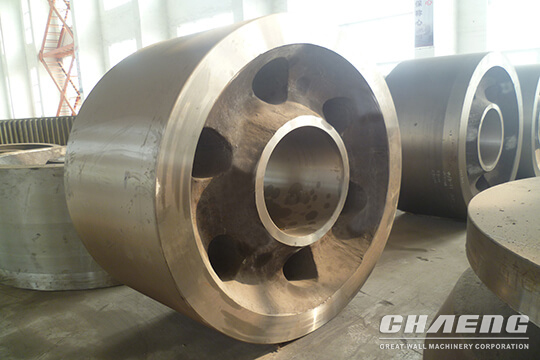

Large Gear Ring

| Weight | 10-35 t |

| Material | ZG45,ZG42CrMo |

| Customizable | Yes |

Girth gear,also called girth gear or gear wheel,which is the major component used in rotary kiln and ball grinding mill which is required to be operated in a long time. So, the quality requirements during the actual production for the big gear ring are very high.

Product Features:

- The particular heat treatment technology is used for the big gear ring manufactured by Xinxiang Great Wall Machinery which makes the improvement in the structure optimization and the hardness of the product. The performance of wear-resistant and anti-impacting are also enhanced greatly.

- The high strength steel was used by us in manufacturing the big gear ring. We also take the optimization for the product against the operation characteristics of the rotary kiln to ensure the stability of the component during the long time operation and extend the service life of the component.

- Our company has rich production capability in steel castings. For the components such as the girth gear ring, we can provide them in large production quantity with short cast period and large amount.

Casting Steel Manufacturing Process:

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

Cases:

Great Wall Casting’s big gears are applied in rotary kiln and ball mill for Turkey Tracim cement company,besides,we have many other cases as follows:

- Xinjiang Tianshan Building Material Group ordering 23t gear ring for rotary kiln.

- Henan Mengdian Group ordering 15t gear ring for cement ball mill.

Our service

Pre-sales Planning

Be a good staff and assistant of the customer, and make sure every investment get high return.

- Provide suggestions for the customer about steel castings production according to customer demand or drawing size.

-

Design the manufacturing process of casting parts according to customers' special requirements.

-

Engineering technicians make site planning and design for customers on site.

After-sales Service

The end of sales is not the end of our service. Continuous and reliable service will save your worries.

- Send professional after-sales people on site to assist our customer in installation and debugging.

- Provide train for operational staff.

- Our casting warranty is one year, during which maintenance is free.

- If any problem comes up, please contact with us at any time. We will send professional technician on-site service.

Application

- cement ball mill

- coal ball mill

- slag ball mill

- cement rotary kiln

- lime rotary kiln