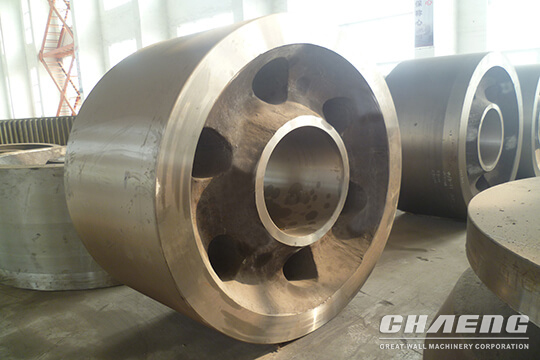

Grinding Roller

| Weight | 20-120 t |

| Material | ASTM:1030 / DIN: 30Mn4 |

| Customizable | Yes |

Grinding roller is the core part of vertical roller mill. We can provide the customization service according to different processing requirements from the customers. In addition, we can provide the grinding roller in the state of finished parts including casting, finish machining, overlaying, which gained good reputation from customers.

Product features:

- Grinding rollers produced by Great Wall Casting have features of high hardness, good anti-cracking and strong wear-resistant capability.

- During grinding roller production, technicians carry out finishing processing with arc air gouging, which can guarantee outlook quality of steel castings.

- We promise that, all the grinding rollers shall be NDT inspected on the stress surface through routing testing methods to ensure that each grinding roller is qualified before leaving our factory. Any sub-standard product is forbidden to leave factory.

Casting Steel Manufacturing Process:

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

Cases

Great Wall Casting supplies grinding roller for international well-known vertical mill manufacturer- Denmark FLSmidth Company.Besides,we have many other customer cases as follows:

- Hubei Building Material Company ordering 85t Grinding Roller for cement mill.

- Shandong yizhou cement co., LTD ordering 60t Grinding Roller for coal mill.

Our service

Pre-sales Planning

Be a good staff and assistant of the customer, and make sure every investment get high return.

- Provide suggestions for the customer about steel castings production according to customer demand or drawing size.

-

Design the manufacturing process of casting parts according to customers' special requirements.

-

Engineering technicians make site planning and design for customers on site.

After-sales Service

The end of sales is not the end of our service. Continuous and reliable service will save your worries.

- Send professional after-sales people on site to assist our customer in installation and debugging.

- Provide train for operational staff.

- Our casting warranty is one year, during which maintenance is free.

- If any problem comes up, please contact with us at any time. We will send professional technician on-site service.

Application

- Vertical Raw Mill

- Vertical Coal Mill

- GGBS Vertical Roller Mill

- Vertical Cement Mill