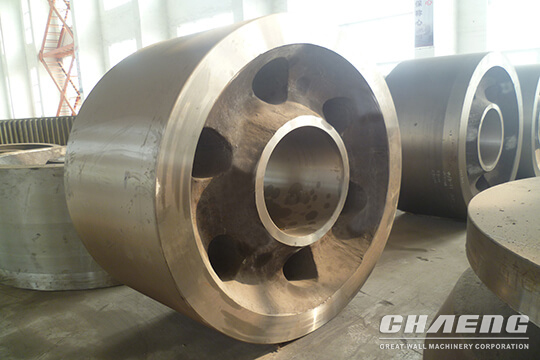

kiln Support Roller

| Weight | 7~42 t |

| Material | ASTM: 1055 / DIN: 42CrMo4 |

| Customizable | Yes |

Support roller,also called support wheel or supporting wheel,which bears the whole weight of rotary kiln (including barrel, inside bricks, heat exchange device inside kiln, raw material, rolling ring, gear ring), which makes the barrel and the rolling ring rotates smoothly on kiln support roller. Therefore supporting roller with strong endurance has become one important standard to judge quality of rotary kiln.

Product Features

- Bear heavy load, good continuous operation,Great Wall Casting adopts ZG55, ZG42CrMo etc. so as to guarantee the quality but also has advantages of bearing heavy load and good continuous operation.

- Simple structure, easy adjustment and repair,Great Wall Casting adopts rolling bearing wheel and has the characteristics of simple structure, convenient maintenance.

- Using process of normalizing and tempering,high product hardness,Great Wall Casting adopts process of normalizing and tempering, surface hardness of encircle is more than 200HB to ensure its great quality.

Casting Steel Manufacturing Process:

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

Cases:

- Hubei Building Material Company ordering 15t support roller for cement kiln.

- Weihui Chunjiang Cement Co., Ltd.ordering 17t support roller for lime production line.

- Meng Electric Cement Co., Ltd. ording 2 units of 21t support rollers for 2*3000t/d Cement Plant.

- Deng Electric Group Cement Co., Ltd.ording ording 30t support roller for 5000 t/d Cement Plant.

Our service

Pre-sales Planning

Be a good staff and assistant of the customer, and make sure every investment get high return.

-

Provide suggestions for the customer about steel castings production according to customer demand or drawing size.

-

Design the manufacturing process of casting parts according to customers' special requirements.

-

Engineering technicians make site planning and design for customers on site.

Provide suggestions for the customer about steel castings production according to customer demand or drawing size.

Design the manufacturing process of casting parts according to customers' special requirements.

Engineering technicians make site planning and design for customers on site.

After-sales Service

The end of sales is not the end of our service. Continuous and reliable service will save your worries.

- Send professional after-sales people on site to assist our customer in installation and debugging.

- Provide train for operational staff.

- Our casting warranty is one year, during which maintenance is free.

- If any problem comes up, please contact with us at any time. We will send professional technician on-site service.

Application:

- cement rotary kiln

- lime rotary kiln

- rotary dryer

- drum dryer