1500 t/d Cement Plant

| Application | Cement Plant, Thermal Power Plant |

| Annual Output | 450,000 tons |

| Process Type | New Dry Process |

| Blaine Fineness | 3300-3800 cm²/g |

The new dry process cement production line with capacity of 1500 t/d built by Xinxiang Great Wall Machinery Co., Ltd. adopts scientific production technology on design and new advanced equipment, which can improve the equipment level of the production line and ensure the realization of design index.

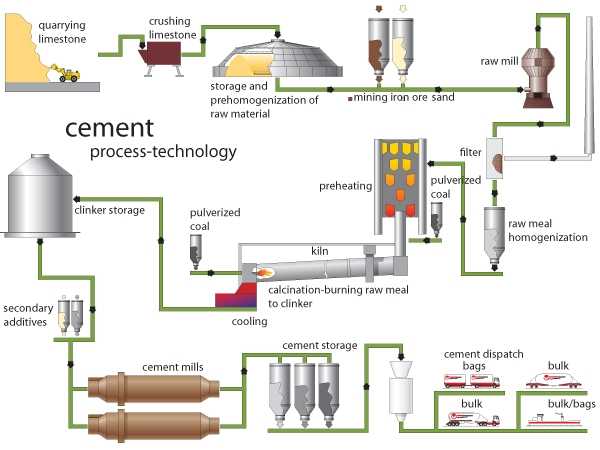

Working Process:

Cement plant is composed of raw materials preparation, raw meal grinding, raw meal homogenization, clinker burning, cement mill grinding, packaging, delivery and so on. The cement equipment in the production line include: raw materials vertical roller mill, vertical coal mill, cement rotary kiln, cement ball mill, cyclone preheater and grate cooler, etc.

Configuration

| Flow sheet | Product | Model | Specification |

|---|---|---|---|

| Limestone Crush | Apron Feeder | B1250 X 1150mm | Feed size: 800m Power: 30kW Output: 350t/d |

| Hammer Crusher | TKPC16.18 | Feed size: 800mm Discharged Particle size: ≤25mm Power: 350kW Output: 250t/h |

|

| Limestone Homogenizing | Stacker | Stack Capacity: 600t/h Reclaiming capacity: 250t/h |

|

| Raw Material Grinding | Vertical Roller Grinding Mill | GRMR30.31 | Feed size: ≤50mm Final product: 12%-15%≥80μm Moisture: ≤7% Power: 1000kW Output: 120t/h |

| Conditioning tower | φ7.5x26m | Blast capacity: 400000m³/h Feed side: 340℃ Discharged side: 150-200℃ |

|

| High temperature fan | Quantity of flow: 400,000m³/h Total head: 7500Pa Temperature: 340℃ Power: 1250kW |

||

| Preheat & Calciner system | Cylone Preheater Calciner furnace | 1 | C1: 2-Φ4300mm C2: 1-Φ5600mm C3: 1-Φ5600mm C4: 1-Φ5900mm C5: 1-Φ5900mm Calciner: Φ6300mm |

| Calcining system | Rotary kiln | φ3.5x54m | Capacity: 1500t/d Pitch: 3.5% Rotating speed: 0.396-3.96 Power: 220kW |

| Cooling system | Inflatable beam grate cooler | LBTF1700 | Capacity: 1500t/d Effective area: 61.8m² |

| Clinker grinding | Cement Vertical Roller Grinding mill | GRMK40.41 | Blain test: 3300-3800cm²/kg Power: 2500kW Output: 115-125t/h |

| Cement packing | Rotating packing machinex2 | Weight Measuring: ±0.25kg/bag Packign Capacity: 90t/h |

Our Product Features:

Powerful Crush and Scientific Stockpiling

The new dry process cement production line with capacity of 1500 t/d build by our company is rationally equipped with advanced equipment for grinding the majority of raw materials. TKPC16.18 single-section hammer crusher is used to crush the limestone, whose feeding size is 800 mm, production capacity is 250 t/h, and annual utilization rate is 25.51%.

Scientific material piling and taking technology is used in the design of this production line adopts to achieve the initial raw material homogenization. Thus the stock ground has the function of both storage and homogenization.

Low Energy Consumption in Grinding Process and Reasonable Homogenization

The energy consumption in cement grinding process accounts for more than 60% of the whole production line, therefore, it has great significance in product quality assurance and energy consumption reduction by using high efficiency and energy-saving GRM series vertical roller mill to deal with all kinds of materials.

The line is equipped with φ15×50mMF homogenization silo which integrates raw meal storage and homogenization. The raw material reserve is 6500 t, with 2.86 d storage life.

Preheating before Calcination with High Efficiency and Energy Saving

Raw materials are sent into φ3.5×54m rotary kiln to be calcined after preheating and precalcining in the cyclone preheater. That is conducive to improve the production efficiency of kiln system, shorten rotary kiln length, and reduce the heat consumption of clinker calcining.

Energy Saving in Grinding Process and Easy Operation

GRMK40.41 (2 + 2) cement vertical mill developed by our company is used on Clinker grinding equipment. It uses the exhaust stem of preheater outlet (300-330) as the drying heat source. Cement vertical roller mill has the characteristics of simple technological process, safe and reliable operation, high grinding efficiency, low power consumption, less maintenance, and short debugging cycle, etc.

Our Services:

1.Engineering Consulting. Great Wall Machinery Technology Support Department is responsible for engineering consulting.

2.Mine Design. Three parts of mine design: feasibility study, preliminary design and construction plan.1. Feasibility study; 2.Preliminary design; 3.Working drawings

3.Equipment Manufacture. Installation of cement plant equipment is a very careful work with strong practicality. Any error may lead to low recovery which cannot reach the expectation.

.

4.Personnel Training. It is simultaneous for worker training and installation & commission in order to save time and cost.