5000 t/d Cement Plant

| Application | Cement Plant |

| Capacity | 5000 tons per day |

| Process Type | New Dry Process |

| Blaine Fineness | 3300-3800 cm²/g |

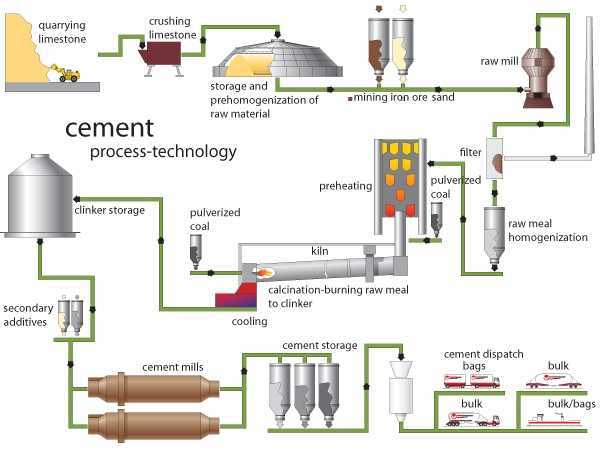

CHAENG(Xinxiang Great Wall Machinery) has a history of more than 50 years and has accumulated rich experience in cement machinery. At present, we have been able to supply 300-5000 t/d cement EP project, providing solutions for the world's growing demand for cement. 5000 t/d cement production line designed by Chaeng, fully learns from the lessons and experiences of more than 20 years of NSP production line design,and combines with today's international advanced production concept to optimize design. It’s composed of raw materials preparation, raw meal grinding, raw meal homogenization, clinker burning, cement mill grinding, packaging, delivery and so on. The cement equipment in the production line include: raw materials vertical roller mill, vertical coal mill, cement rotary kiln, cement ball mill, cyclone preheater and grate cooler, etc.

5000TPD cement plant process:

Additive materical’s crushing and storage——Dosing——Limestone‘s crushing and storage——Dusting collecting system——Raw meal homogenizing——Raw mill grinding (Raw mill)——(Coal homogenizing——Coal mill grinding)——Preheating and precalcining system——Rotary kiln calcined (rotary kiln)——Cooler——Clinker storage——Cement Grinding (cement mil)——Additive material crushing——Cement storage——Transportation in bag——Transportation in bulk

Configurations:

| Purpose/ description | Equipment name | Type / specifications |

|---|---|---|

| Limestone crushing | Hammer crusher |

Feeding material size: < 1100mm Discharging material size: < 75mm Crushing capacity: 700t/h |

| Siltstone crushing | Jaw crusher |

Feeding material size: < 750mm Discharging material size:< 150mm Crushing capacity: 200t/h |

| Cone crusher |

Feeding material size: < 150mm Discharging material size: < 30mm Crushing capacity: 200t/h |

|

| Limestone homogenization stockyard | Cantilever stacker Bridge-type scraping reclaimer | Stacker capacity: 1400t/h |

| Reclaimer capacity: 500t/h | ||

| Reclaimer capacity: 500t/h | Mobile stacker | Stacker capacity: 200t/h |

| Chain-plate type stacker | Reclaimer capacity: 110--130t/h | |

| Raw coal homogenization stockyard | Movable trolley type stacker | Stacker capacity: 200t/h |

| Bridge-type scraping reclaimer | Reclaimer capacity: 100t/h | |

| Raw material grinding, and waste gas treatment | vertical roller mill |

Grinding capacity: 360-400t/h Feeding material moisture content: < 6% Discharging material moisture content: < 0.5% Feeding material size < 100mm Discharging material size: 80μm Screen residue: < 12% |

| Draught fan for raw material mill |

Airflow: 860,000m3/h Total pressure: 9500Pa |

|

| Draught fan at kiln tail |

Airflow: 860000m3/h Total pressure: 7500Pa |

|

| Electrostatic precipitator |

Filtering area: 310m2 Airflow: 820,000m3/h Outlet dust content: ≤50mg/m3 |

|

| Pulverized coal preparation | Vertical coal mill |

Grinding capacity: 38~45 t/h Feeding material moisture content: < 12% Discharging material moisture content: < 1% Feeding material size < 25mm Discharging material size: 80μm Screen residue: < 12% |

| Calcining system | Rotary kiln |

Size: Φ4.8×74m Inclination: 4% Support bases: 3 Rotation speed: 0.6~4.0r/min Installed power: 630kW Production capacity: 5000t/d |

| Preheater and decomposition furnace |

Double five-stage preheater + decomposition furnace Cyclone 1: 4-Φ5.0m Cyclone 2: 2-Φ6.9m Cyclone 3: 2-Φ6.9m Cyclone 4: 2-Φ7.2m Cyclone 5: 2-Φ7.2m Decomposition furnace: Φ7.2×30.0m Production capacity: 5000t/d |

|

| Flow-control type grade cooler |

Cooling area: 119.6m2 Feeding material temperature: 1400℃ Discharging material temperature::65℃ |

|

| Electrostatic precipitator at kiln head |

Airflow: 550,000m3/h Filtering area: 196m2 Inlet dust content: ≤30g/m3 Outlet dust content: ≤50mg/Nm3 |

2500 t/d Cement Plant Features:

Great wall machinery is one of the domestic first-class grinding system integration suppliers. With the advantages of technology, equipment and brand of ball mill, rotary kiln, vertical roller mill for nearly 6 years, Great Wall Machinery devotes itself to carry out business service in many fields and gradually expend the business mode including EPC project, financial leasing and spare parts supply as the increasing maturity of single equipment and turnkey project, successfully realizing the change from manufacture to manufacture + service.

1.Advanced Technology Brings Lower Power Consumption.

Compared with traditional cement production line, the 5000t/d cement plant designed by Chaeng uses lower energy consumption equipment in the main part of energy consumption, such as vertical raw mill, vertical coal mill, vertical cement mill, etc., and the energy saving effect is very significant, which can reduce energy consumption with an average of 15-20 kWh/t.

2.Reasonable Design, Reduces Dust and Noise Effectively

Cement production has always been one of the leading causes of environmental pollution, thus more and more cement plant is looking for a solution to reduce noise and dust pollution. Chaeng fully considers the sustainable development in the design, reducing dust through campus greening, filter, etc. Since the introduction of noise control programs in key areas, the factory noise is lower than the national standard.

3.Shorter Delivery Time, Earlier Profits

With large supporting cast steel companies and large machining workshop, Chaeng has 120 t casting ability, can supply complete spare parts. Furthermore, with a variety of long-term cooperation and first-class equipment suppliers, it greatly shortens delivery cycle, and makes your profit in the shortest possible time.