Active Lime Production Line

| Application | Mining, Quicklime Plant |

| Capacity | 150-1000 t/d |

| Motor Power | 160-630 kW |

Chaeng (Great Wall Machinery) can undertake the 200-1500 t/d activity lime production line EPC, including the reach report, civil engineering, designing equipment, installation and debugging---"turnkey" service with production capacity and standard achieved.

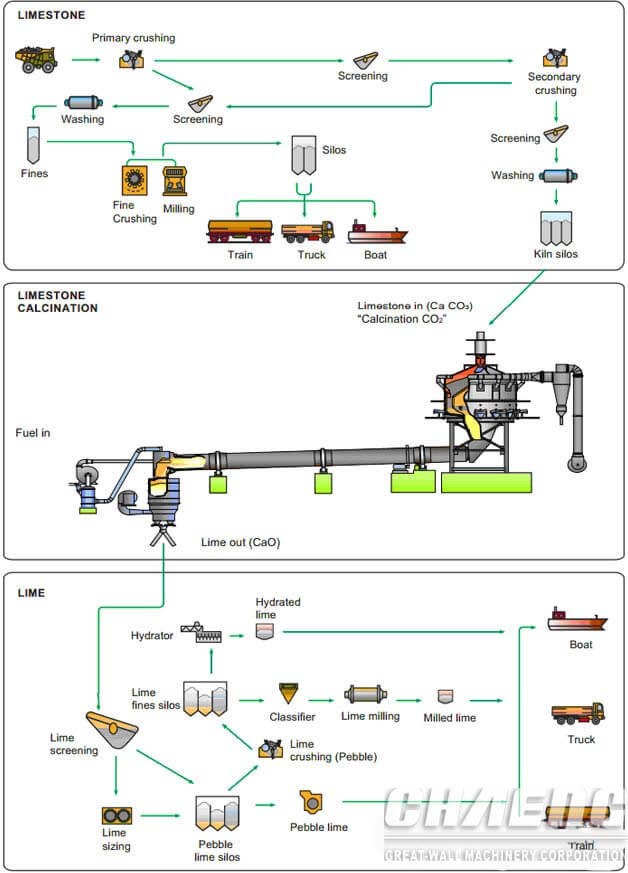

Working process:

1. Raw Material Conveying:

The 20-40mm limestone on the stock ground is sent to storage silo by the B1000 belt conveyor with large inclination. In the storage silo, qualified limestone with granularity more than 10mm will be sent to the gravel silo, while limestone with granularity less than 10mm will be conveyed to the powder silo.

2. Limestone Calcining:

The limestone calcining system is mainly made up of 10.5×8.5m vertical preheater, 4.0×60m rotary kiln and vertical cooler whose output is 600t/d and heat consumption of 5.75GJ/t. Limestone inside the preheater is heated by high-temperature gases from rotary kiln to 600-800°C, at which temperature limestone can be partly decomposed. Then the limestone will be sent by 12 hydraulic push rods to the kiln end, where it will be undergone high-temperature calcination before sent to the vertical cooler. The processed limestone will be cooled down by cold air to 65°C. Air from the vertical cooler enters into the rotary kiln as the second air to take part in calcining process.

3. Finished Product Conveying:

The final lime will be sent to the storage bin for final products by NE500 bucket elevator. After screening, qualified lime whose particle size is more than 5mm will be sent to storage for active lime, while powder lime whose size is less than 5mm will be sent to storage bin for powder.

4. Gas Treating:

High-temperature gases from rotary kiln will do heat exchange with limestone inside the preheater, and after that, the temperature of these gases will reduce to lower 280°C. Then these gases will be cooled down by multi-tube cooler to 200°C lower. Finally, they enter into the bag filer before discharged into the atmosphere.

Configuration

| designed capacity (T/D) | 200 | 300 | 400 | 600 | 800 | 1000 | |

|---|---|---|---|---|---|---|---|

| product | active lime | active lime | active lime | active lime | active lime | active lime | |

| preheater | specifications | RS-6.5×3.4 | RS-7.5×3.4 | RS-8.5×3.4 | RS-10.×3.4 | RS-10.8×3.4 | RS-13.5×3.4 |

| Number of push rod | 6 | 8 | 10 | 12 | 16 | 18 | |

| kiln | specifications | φ2.8×42M | φ3.3×50M | φ3.6×56M | φ4×60M | φ4.3×66M | φ4.8×68M |

| Effective volume (m³) | 190 | 292 | 430 | 575 | 738 | 1005 | |

| speed (r/min) | 0.45-2.22 | 0.2-1.9 | 0.22-1.57 | 0.48-1.57 | 0.21-1.57 | 0.19-1.98 | |

| Cooler | specifications | LS-3×3 | LS-3.6×3.6 | LS-3.8×3.8 | LS-4.1×4.1 | LS-4.7×4.7 | LS-5.2×5.2 |

| Feed temperature | 1100±50℃ | 1100±50℃ | 1100±50℃ | 1100±50℃ | 1100±50℃ | 1100±50℃ | |

| Discharge temperature | <100℃ | <100℃ | <100℃ | <100℃ | <100℃ | <100℃ | |

| Weight(T) | 35 | 40 | 50 | ||||

| heat rate (KJ/Kg) | 5200 | 5200 | 5100 | 5000 | 5000 | 5000 | |

| Activity (50g,4NHCL,10MIN) | ≥360ML | ≥360ML | ≥360ML | ≥360ML | ≥360ML | ≥360ML | |

Our Product Features:

1. Large production. Maximum capacity can reach 1500t/d

2. Quality of final product is well-distributed, and over-sintering is no more than 8%.

3. Activity of lime can reach 400ml

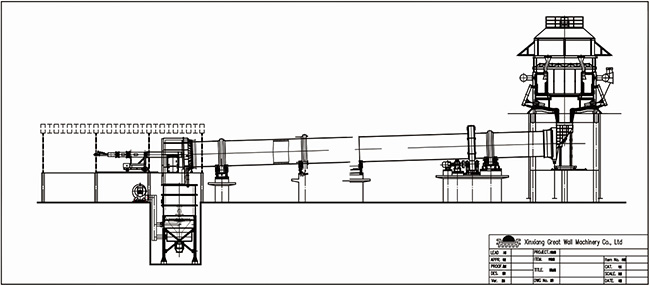

Main structure of Active Lime Production Line:

Main structure of vertical cooler

Grate bar and discharge device for big block

Cooling chamber lower the cooler

Support Device

Main structure of rotary kiln

1. Body

2. Riding wheel

3. Gear ring

4. Tire

5. Transmission device

Main structure of vertical preheater

Upper feeding system: upper material bin, feeding chute

Preheater body: preheater chamber, suspension device

Stacker device: stacker part, frame, connecting rod.

Hydraulic system

Our service:

| Pre-sale Service | Sale Service | After-sale Service | |

|---|---|---|---|

| Reception service | airport/Train station pick up | Customized suitable installation plan according to your requirements | Lifetime technical support:one year quality warranty and life time technical support |

| Hotel reservation | Sending technicians and workers to the client site or build | ||

| Visit arrangement | Adjusting & Training operators to finish the inspection ad together width you | ||

| Other personalized service | |||