Flotation Machine

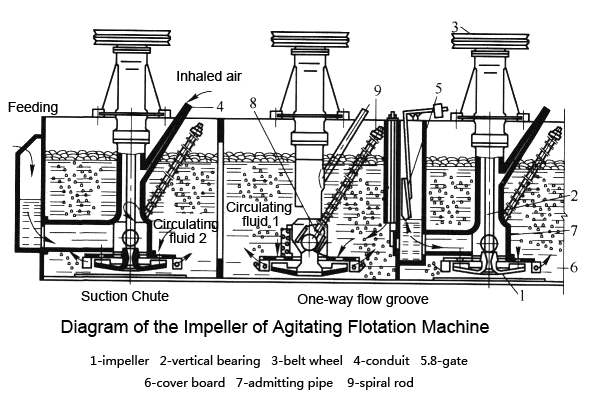

Flotation machines constitute the basic equipment for useful minerals recovery from non-ferrous ores and other raw materials by flotation. Flotation machine used for sorting colored ofblack metal, and also for non-metallic such as: coal, fluorite and talc. It starts work through the triangle-generation drive motor driven impeller rotation, a centrifugal role in the formation of negative pressure, on the one hand inhalation of sufficient air and mixture with slurry, while stirring the pulp mixed with drugs, while refined foam, so that mineral adhesive on top the of foam, and then float to the surface of mineralized, and form slurry bubble. Adjust the ram height, control liquid surface, so that scraper scraping the useful foam.

When flotation machine works, slurry is inhaled from the bottom of the cell to the space between impellers. Meanwhile, the low-pressure air send by fan is sent to this area through the air distributor in the hollow shaft. After sufficient mixing, the slurry is pushed out by the impeller, and then goes to the whole cell. When the froth rises to the stable level, after the enrichment processing, froth overflows to the froth trough from the overflow weir. Another part of ore slurry flows to lower part of impeller for the re-mix with air. The remained slurry flows to the next cell until becomes tailing.

- Flotation machine has the advantages of large air-absorption capacity and low energy consumption.

- Every cell owns three functions: Air absorption, slurry absorption, and flotation separation, and the cells form a flotation separation loop by itself without any auxiliary equipment, and is allocated horizontally, which favors the change of flow.

- The circulation of mineral slurry is reasonable, and can avoid the disposition of coarse sand to the largest extent. There is self-control device on the surface of mineral slurry, so it is easy to adjust it.

- The impeller has backward-inclined upper and lower vanes, which produce upper and lower circulation of mineral slurry respectively.

Pre-sales Service

1.Offering comprehensive technical and business consultation services;

2.Proposing the most suitable scheme and equipment for our clients;

3.Designing and fabricating targeted products according to the special requirements of clients;

Service on Sale

1.Providing initiative and enthusiastic service;

2.Introducing & Demonstrating products and its application to clients;

3.Helping clients to choose equipments.

After-sales Service

1.Highly inspecting equipments in every working procedure, quality comes first;

2.Fast & Safe Delivery;

3. Assisting our clients for foundation construction of equipments;

4.Dispatching engineers to install and debug equipments;

5. Training the first-line operators on site;

6. Regularly visit clients to solve production problems;

7. Providing life-long maintenance service;

8.Providing technical exchanging;

Application:

Flotation machine are mainly used in mineral ore dressing plants, selecting the valuable mine from gangue. It is applicable for the separation of numerous of mineral ores, such as fluorite and talc, gold ore, copper ore, iron ore and zinc ore and so on.