Lime rotary kiln

| Application | Cement Plant, Clinker Grinding Unit, Thermal Power Plant, Mining, Quicklime Plant |

| Capacity | 150-1500 t/d |

| Motor Power | 160-630 kW |

| Weight | 252-841 tons |

Rotary lime kiln is the main equipment of lime production line. It is widely used for many industries like metallurgy, chemical industry, building refractory materials, environmental protection, etc.

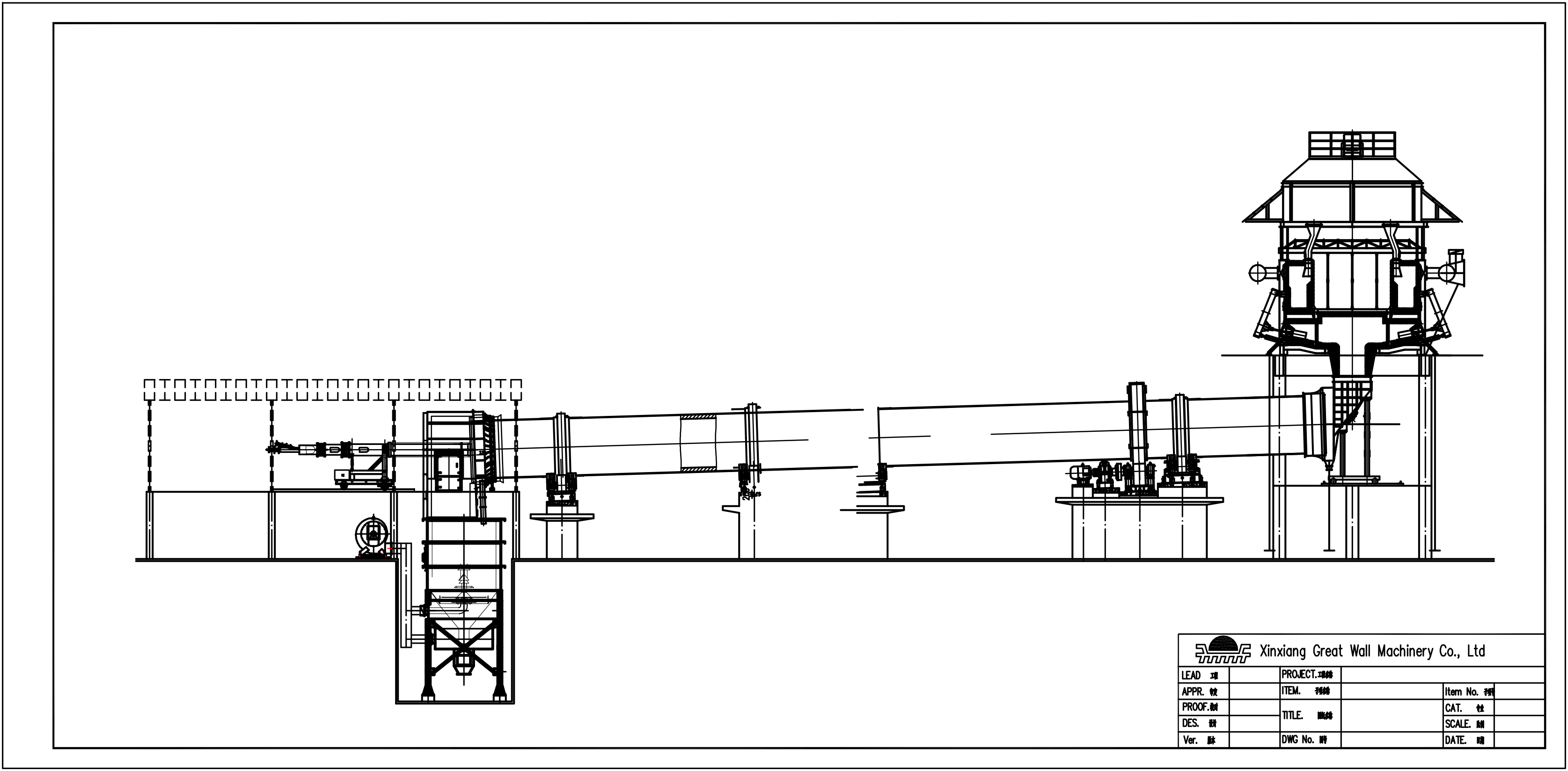

Lime rotary kiln is the main equipment of lime production line. The lime rotary kiln consists of cylindrical shell, supporting device, supporting device of thrust roller, driving unit, moveable kiln head, sealing device on the tail of kiln, coal dust pipe device, etc., the kiln body has a certain tilt angle with level.The whole kiln body is supported by the roller supporting device, and it is also equipped with thrust roller device to control the up and down movement of the kiln body.

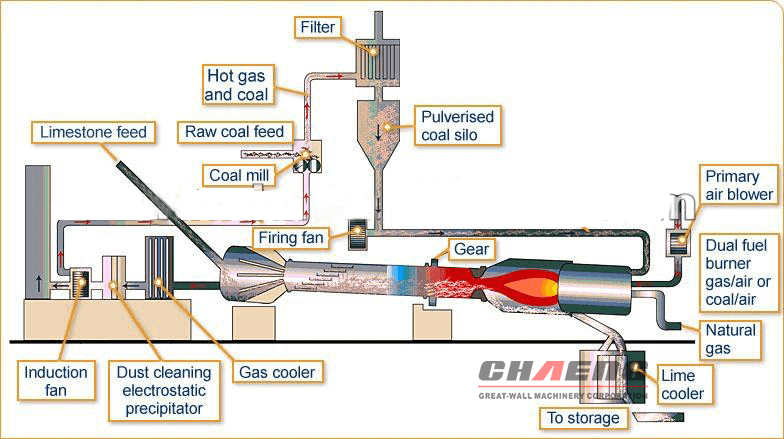

Material will be feed into kiln tail through chute in gas chamber. As kiln shell is inclined and it rotates slightly, material will move along round shell and will also move along shaft direction from kiln tail to kiln head. Material will be processed through pre-heat, decompose, calcined and will be feed into cooler. Fuel will be given through gas or coal burner at kiln head and will be combusted in kiln. Heat will be transferred to material by fire radiate, hot air flow, kiln brick transfer. The heat will heat and calcine material enough and make it final product.![]()

Advantages of rotary kiln to calcine active lime

1. The rotary kiln has high output and is suit for being applied to the large active lime production line. In the world now, there is lime rotary kilns with the capacity of 2,200t per day being put into production; many 150-300 t/d lime rotary kilns have been established and run well at home and abroad. The rotary kiln can also be adopted by middle and small-sized enterprises.

2. The rotary kiln is open-calcination kiln with simple structure, and the sulfur-containing flue gas can be discharged timely without the adhesion of the sulphur materials, which makes the sulphur content of the product be low and meet the steelmaking requirements. In addition, the materials evenly roll forward in the kiln and are evenly heated, so the the quality of the product is stable with low underfiring and overfiring rate, and the rotary kiln can calcine the lime with high activity for steelmaking. Under the same conditions, the activity degree of the lime produced by the rotary kiln is higher (averagely 30ml higher) than the activity of the lime produced by the gas kiln, and generally the activity degree of the lime produced by the rotary kiln is 340-380ml even up to 400ml.

3. The rotary kiln can directly calcine the 10-50mm limestone. For general mines, the 0-30mm limestone which can not be processed by other kiln type accounts for 30-40% of the total output. And with the raw materials of the iron and steel being more refined, the limestone is gradually replaced by the quick lime in the sintering process and the fine-sized limestone can not be comprehensive utilized. Building a production line with rotary kiln can not only utilize high-quality limestone mine, but also achieve the sustainable development of the lime industry.

4. Equipping a vertical preheater at the kiln tail can fully utilize the high-temperature flue gas to preheat the limestone with normal temperature to the initial decomposition state, which can not only enormously improve the output of the rotary kiln, but also fully reduce the heat consumption of the unit product.

5. Equipping a vertical cooler at the kiln head can not only suddenly cool the high-temperature lime and improve the activity of the product, but also be convenient for transporting and storage. It can also obtain the secondary air entering the kiln with higher temperature, which can efficiently improve the firing temperature in the kiln and reduce the fuel consumption.

6. The flue gas discharged from the vertical preheater at the kiln tail has low temperature, about 280-350℃ with low dust content about 20g/Nm3, which makes the configuration of the follow-up flue gas treatment be simple and efficient to smoothly meet the environmental requirements.

7. The biggest advantage of the rotary kiln is that the quality of the lime it produced is stable.

| Model | Output(t/d) | Main Drive(r/min) | Motor(KW) | Regulating Range(r/min) | Weight(T) |

|---|---|---|---|---|---|

| φ2.2*50 | 96 | 0.125-1.25 | 30 | 132-1320 | 130.71 |

| φ2.5*50 | 130 | 0.516-1.549 | 55 | 440-1320 | 167.5 |

| φ3*48 | 850 | 0.3309-3.309 | 90 | 100-1000 | 237 |

| φ3.2*48 | 1000 | 0.375-3.75 | 160 | 100-1000 | 252 |

| φ3.2*50 | 1200 | 0.398-3.975 | 190 | 150-1500 | 263 |

| φ3.3*52 | 1200 | 0.391-3.91 | 190 | 100-1000 | 280.8 |

| φ4*60 | 2500 | 0.396-3.96 | 315 | 100-1000 | 487.5 |

| φ4.2*60 | 2800 | 0.4165-4.165 | 420 | 100-1000 | 576.1 |

| φ4.3*62 | 3000 | 0.398-3.98 | 420 | 100-1000 | 598.5 |

| φ4.3*64 | 3200 | 0.449-4.49 | 450 | 100-1000 | 585 |

| φ4.5*66 | 4000 | 0.41-4.1 | 630 | 100-1000 | 710.4 |

| φ4.8*70 | 5000~5500 | 0.4-4.0 | 630 | 100-1000 | 845.3 |

| φ4.8*72 | 5000 | 0.403-4.03 | 560 | 100-1000 | 847 |

| φ4.8*74 | 5000 | 0.35-4 | 630 | 130-1500 | 841 |

Pre-sales Service:

The wide product range enables us to provide our customers with stand-alone machines or complete processing plants. Based on our customers’ request and budget, our experts make efficient, reliable solutions. Following customers’ order we produce strictly, what’s more, before placing the order every customer has the chance to visit XinXiang Great Wall (Chaeng) working machines or complete plant in the site.

To ease the trip for every visitor to China, in particular the first-time visitor, we provide FOR FREE all relevant visitor-friendly services including invitation letter preparation, hotel reservation, airport pick-up, incity transportation, and sightseeing guide, et

After-sales Service:

Experienced technicians guidance is available on the phone, and on the internet. One or more engineers will be dispatched to the quarry site to help install the customers’ plants. Necessary training about machine daily maintenance to local workers is provided also.

After-Sales department is made of well-trained employees and installation engineers, the installation engineers are special and professional members of XinXiang Great Wall (Chaeng), they are now strategically located home and abroad, working for our customers.

Application:

Rotary Kiln is a kind of thermal equipment calcines lump, bulk and slurry materials. It is widely used in cement & construction, non-ferrous metals, lime, ferrous metals, refractory materials, industrial chemicals, paper making industries etc