Grinding Table

| Weight | 20-132 t |

| Material | ASTM: A570 / BS: S235JR |

| Customizable | Yes |

The grinding table is one of the key parts of vertical roller mill. It includes drag rings, segments (lining plate) and bases. The optimization and improvement are made by us on the traditional grinding table casting technology, that the most advanced sodium silicate-bonded sand molding technology, to overcome the deficiencies in structure and make the grinding base bear force equivalently. All of these avoid the problem of material’s washout on the not wear-resisting surface.

Product Features:

- The grinding tables produced by us have the features of high hardness, good anti-cracking.

- We carry out the grinding table dressing and finishing machining by the equipment of arc air gouging and shot-blasting, which can guarantee the quality of the steel castings.

- Before delivery, all the grinding tables shall have NDT inspection several times as per perfect inspection flow. Any of defective products is forbidden to leave the factory.

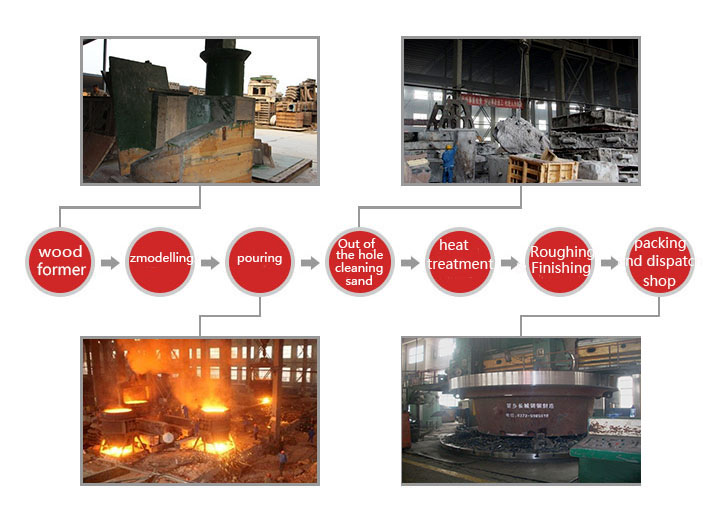

Casting Steel Manufacturing Process:

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

Case:

The grinding table is applied to vertical mill GRMK46.41 with annual capacity of 0.9 million tons cement in Henan Yuhui Huanghe Construction Materials Co., Ltd. At present, the mill runs in good condition and won reputations in our China customers,besides,we have many other cases as follows:

- World Steel-Mittal Group ordering 110t grinding table for cement mill

- Meng Electric Cement Co., Ltd. ordering 83t grinding table for slag mill

- Denmark FLSmidth ordering 76t grinding table for slag mill

Our service:

Pre-sales Planning

Be a good staff and assistant of the customer, and make sure every investment get high return.

- Provide suggestions for the customer about steel castings production according to customer demand or drawing size.

-

Design the manufacturing process of casting parts according to customers' special requirements.

-

Engineering technicians make site planning and design for customers on site.

After-sales Service

The end of sales is not the end of our service. Continuous and reliable service will save your worries.

- Send professional after-sales people on site to assist our customer in installation and debugging.

- Provide train for operational staff.

- Our casting warranty is one year, during which maintenance is free.

- If any problem comes up, please contact with us at any time. We will send professional technician on-site service.

Application:

- Vertical Raw Mill

- Vertical Coal Mill

- GGBS Vertical Roller Mill

- Vertical Cement Mill