Preheater System

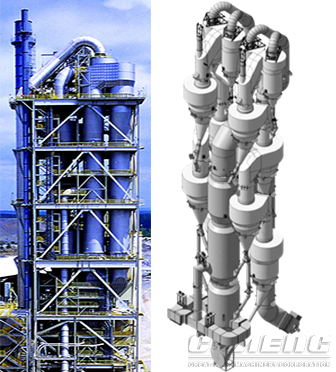

After extensive research and data from the existing preheater systems, and at the same time considering the characteristics of raw materials and fuels available in cement plants, the latest generation of CHAENG preheater system represents a comprehensive upgrade from earlier generations. This updated system features optimized process and environmental performance.

While operating with low system resistance and energy consumption, it will further contribute to reduced investment in construction investment. Also the level of emission of harmful components in the exhaust gas, such as NOx, and Sox has been significantly improved.

The new design allows to make use of the full value of resources. It also permits to utilize all kinds of wastes as alternative fuels or additives, which allows the plant to develop towards an ecological, greener production. With environmental and ecological concerns, this new system is not only more cost effective but also more environmentally friendly.

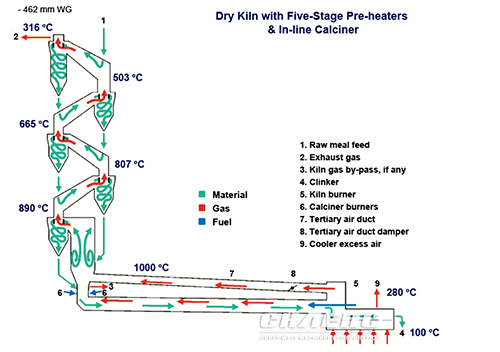

CHAENG Calciners are designed as suspension tube calciners to ensure:

- An even distribution of raw meal, fuel and combustion air across

- The entire Preheater System section

- Complete burn-out of the fuel

- Optimum heat transfer between fuel and raw meal

- High calcination rate up to 95 percent

The standard calciner for oil and gas is the Preheater System compact swirl chamber. The Preheater System is the standard calciner for using solid fuels. Both calciners have proved their capabilities of reaching emission limits of worldwide legislation without the use of additives. The reduction of NOx emissions in the Low NOx calciner is based on the principle of “continuous staged combustion” and reaches the “BAT” emission level (best available technology).

Technical Characteristics of the Latest Generation Preheater System:

Technical Characteristics of the Latest Generation Preheater System:

- Suitable for production lines of 300 t/d~10000 t/d

- Suitable for a wide range of raw materials and fuels; the precalciner is uncomplicated in structure and easy to operate.

- Ready solutions for different fuels, including bituminous coal, anthracite, inferior coal, heavy oil, crude oil and natural gas.

- Available by-pass solutions for raw meal or fuels with high alkali or chlorine Content

- NOx-reduction by fractional combustion in the precalciner by up to 50%; up to 70%with SNCR

- A wide range of solutions for converting daily garbage, industrial wastes, sludge and toxic waste into resources and breaking up toxic materials into their harmless components , thus reducing actual overall pollution

- Relatively low exhaust gas temperature, low pressure loss and energy consumption; highly efficient cyclone designed f Structural Features: or separating materials and gas.

Structural Features:

Structural Features:

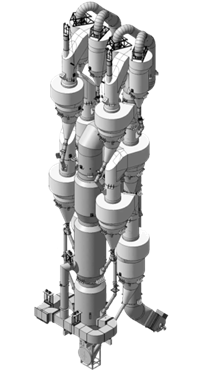

High volume calciner providing for high precalcination rate; available calciners in different designs, including curved duct structure, triple-section structure and combined structure

Adaptability to different types of coal, pet coke, heavy oil and natural gas; adaptability to alternative fuels with their specific heat value

Reduced NOx emission by well-designed layout for calciner burners and tertiary air inlets

Cyclones designed for high separation efficiency and low pressure loss

Segmented inner tubes made from new type of heat-resistant cast steel, providing for long service life and easy Maintenance

Fixed splash plates are arc-shaped, which can better distribute materials and increase heat exchange efficiency

Flexible flap valves with good sealing effects, which prevent airflow blockage and facilitate easy maintenance

Fabricated Preheater Structure

CHAENG specialises in design of fabricated structures for Preheater tower. The unique design of preheater columns will ensure speedy erection .

Pre-sales Service:

The wide product range enables us to provide our customers with stand-alone machines or complete processing plants. Based on our customers’ request and budget, our experts make efficient, reliable solutions. Following customers’ order we produce strictly, what’s more, before placing the order every customer has the chance to visit CHAENG working machines or complete plant in the site.

To ease the trip for every visitor to China, in particular the first-time visitor, we provide FOR FREE all relevant visitor-friendly services including invitation letter preparation, hotel reservation, airport pick-up, incity transportation, and sightseeing guide, etc.

After-sales Service:

Experienced technicians guidance is available on the phone, and on the internet. One or more engineers will be dispatched to the quarry site to help install the customers’ plants. Necessary training about machine daily maintenance to local workers is provided also.

After-Sales department is made of well-trained employees and installation engineers, the installation engineers are special and professional members of CHAENG, they are now strategically located home and abroad, working for our customers.

Application in cement production line