Manganese Slag Powder Plant

| Annual Output | 200,000-1,500,000 tons |

| Grinding material | Manganese slag |

| Blaine Fineness | 4200-4500 cm²/g |

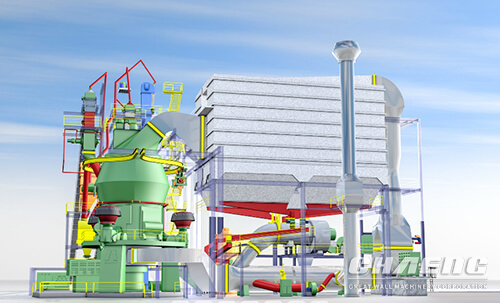

| Matching Equipment | Feed belt +Vibrating screen+Manganese slag vertical mill+hot blast stove+dust collector+warehouse |

CHAENG (Great Wall Machinery) can undertake 20 tons --1.5 million tons of Manganese slag powder plant EPC projects.We can provide raw material testing , engineering design,equipment manufacturing,installation,debugging,technical training,standard production,production contract and "turnkey" service.

CHAENG adhering to the "three heart" service aims to provide customers with pre-sale, sale, after-sale and one-stop total service solution!

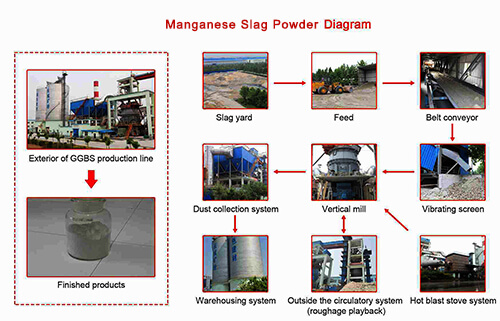

Process Description

Forklift will transfer the Manganese slag from the slag pile to the weighting silo.

during the transportation, the Manganese slag will be magnetized and sieved to remove the iron parts. The pre-processed slag then will be fed to the vertical mill by the elevator for grinding.

After grinding, the Manganese slag will be classified and dried by the hot air generator.

The required Manganese slag powder then will be collected by the dust collector and transferred to the final product ware house by air delivery chute and elevator.

Suggestions for the equipment selection

| Product Specificationsct | GRMS 53.41 | GRMS 46.41 | GRMS 33.31 |

|---|---|---|---|

| Annual production (tons) | 1,000,000 | 600,000 | 300,000 |

| Designed production (t/h) | 150 | 90 | 45 |

| Raw materials input amount (t/h) | 188 | 125 | 65 |

| Actual output (t/h) | 160 | 105 | 55 |

| Final products fineness (m²/Kg) | 500 | 500 | 500 |

| Power consumption (KWh/t) | 26.5 | 28.5 | 30 |

| System power consumption (KWh/t) | 35 | 37 | 42 |

| Coal consumption (equivaient to standard coal) (kg) | 17 | 18 | 18 |

| Metal recovery of per ton slag (%) | 0.2-0.3 | 0.2-0.3 | 0.2-0.3 |

Project Case

CHAENG already has more than 100 customers recently, among which, the capacity of 1 million t/a, 600,000 t/a and 300,000 t/a has occupied more than 80%. The sheet below has showed the main equipment specs and parameters of these three capacities.

Product advantages

1. Supported by large vertical mill with domestic top technology

| System solutions | Ball Mill | Vertical Mill |

|---|---|---|

| System power consumption (kwh/t) | 90 | 45 |

| Drying capacity | Not good | Very good |

| (Separate drying) | (Mill and drying) | |

| Adaptability to size | Not good | Very good |

| Mainly due to the impact operation rate | Run for a certain period to clear the ball down dross | Pressure roller and tray liner wear after repair |

| Scale | difficult | easy |

CHAENG GRMS46.41 manganese slag vertical mill used in manganese slag grinding production line system has won the national patent , which greatly reduces the power consumption for grinding, grinding noise and construction investment, and sets drying and grinding as a whole. It is one of the widely used devices of the current large-scale manganese slag grinding system.

2. Manganese slag powder products are of good quality

2. Manganese slag powder products are of good quality

The slag produced by vertical mill is more even distribution and better liquidity than that produced by ball mill.

3. The specific surface area of product is 450㎡ / kg or more, and has a high activity

Vertical mill production of manganese slag specific surface area of about 450㎡ / kg, mineral powder 28 days to reach maximum activity play, from the experimental data that the incorporation of mineral powder 28D can improve the cement strength of 15% -20%.

4.20 mg / m³, low dust emissions

CHAENG in slag grinding plant construction is very environmentally conscious, the whole production line of negative pressure production, with a sound of dust, noise reduction means for metering bin blanking, powder and other finished products are made of bag filter dust point to govern , product delivery are used in air slides and bucket elevator, greatly reducing dust emissions and its control in 20mg / m³, far below the national standard Chinese 30mg / m³

5. rationalized, saving investment maintenance costs

In order to save infrastructure investment, designed to meet production requirements under the conditions of the device is disposed in the open air as much as possible, so that not only saves construction costs, but also convenient for the factory in the next production process equipment maintenance.

6.System is easy to operate, save a lot of labor costs.

Detailed Technology

- 1.Dry slag and wet slag should be put into the mill separately, it can avoid slag agglomerate and decreasing the transmission capacity.

- 2.External loop system uses embedded scraping machine + elevator + pipe hoist iron remover to reduce dust emissions.

- 3.Set the flow warehouse (middle warehouse) steady before sending the slag into the vertical mill to improve the stability of vertical mill.

- 4.Set dust collector on the chute transportation corridor to improve environmental cleaning rate.

- 5.Add iron elector to achieve iron slag separation and reduce attrition

- 6.Crush big bite of slags again to improve the material utilization rate.

Service Support

To ensure that customers and the entire project is completed smoothly, CHAENG pioneered the industry's first "1 vertical mill, eight service" value-added solutions, from pre-production to the final project, the Great Wall machinery to provide full guidance.