Sand Production Line

Sand making machine is widely suitable for the medium crushing and fine crushing of many types of hard and crisp materials such as rocks, abrasive material, refractory, cement clinker, quartz stone, iron ore and concrete aggregate. The series crushing equipment produced by Chaeng sand making machine manufacturer has such features of low energy consumption, high output and big crushing ratio, and the sand making machine price is the most competitive.

Applications: artificial sand, etc.

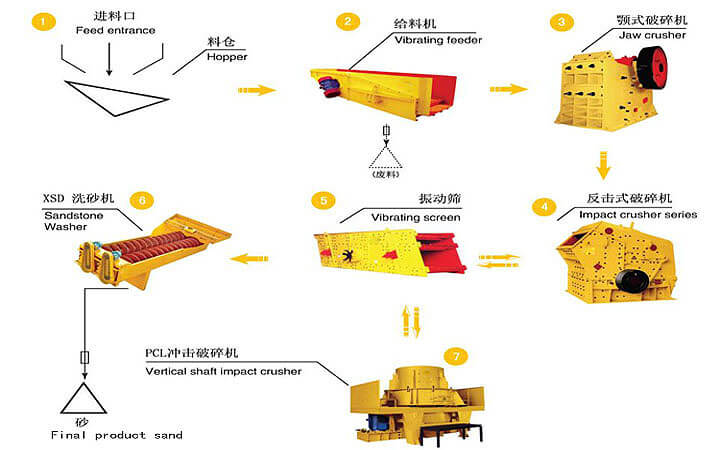

Composition equipment: vibrating feeder, jaw crusher, sand making machine (straight-through impact crusher), vibrating screen, sand washing machine, belt conveyor, centralized electronic control and other

Process description:

Raw materials in big size go trough hopper, and are sent to jaw crusher evenly by vibrating feeder for primary crushing. The crushed materials are sent to cone crusher (or impact crusher) by belt conveyor for secondary crushing, and then the crushed materials are sent to vibrating screen by belt conveyor for screening. The final sand (the final products below the bottom sieve) is sent to sand washer to clean, and then to the final products pile. The bigger pieces stones (stones on the top sieve) will be sent to vertical impact crusher (sand maker) for fine crushing, and then to vibrating screen again for screening. This forms closed and continuously automatic cycles.

Advantage:

1.Low operation cost with high rate of crushing;

2.High Capacity with low pollution;Low work noise

3.Easy maintainence;

4.Simple structure,low cost.

5.High efficiency and energy saving.

6.Automatic lift system,quick and easy replacement of wear parts.

7.The end products with cube shape.

8.The manufacture sand meet the national standard of building sand. It is epigranular, cubic shape and reasonable gradation of sand.

Specification:

| Model | ImpellerSpeed(r/min) | Max Feed-in size(mm) | Capacity (t/h) | MotorPower(KW) | Weight(T) | Overall Dimensions(mm) |

|---|---|---|---|---|---|---|

| 600 | 2000-3000 | 30 | 12-30 | 2*30 | 5.6 | 2800*φ1500*2030 |

| 750 | 1500-2500 | 35 | 25-55 | 2*45 | 7.3 | 3300*φ1800*2440 |

| 900A | 1200-2000 | 40 | 55-100 | 2*55 | 12.1 | 3750*φ2120*2660 |

| 900B | 1000-1450 | 40 | 65-130 | 2*75 | 13.6 | 3750*φ2300*2090 |

| 1050 | 1000-1700 | 45 | 100-160 | 2*(90-110) | 16.9 | 4480*φ2450*2906 |

| 1250 | 850-1450 | 45 | 160-300 | 2*(132-180) | 22 | 4563*φ2650*3716 |

| 1350 | 800-1193 | 50 | 200-360 | 2*(180-220) | 26 | 5340*φ2940*3650 |

Pre-sales Service:

The wide product range enables us to provide our customers with stand-alone machines or complete processing plants. Based on our customers’ request and budget, our experts make efficient, reliable solutions. Following customers’ order we produce strictly, what’s more, before placing the order every customer has the chance to visit CHAENG working machines or complete plant in the site.

To ease the trip for every visitor to China, in particular the first-time visitor, we provide FOR FREE all relevant visitor-friendly services including invitation letter preparation, hotel reservation, airport pick-up, incity transportation, and sightseeing guide, etc.

After-sales Service:

Experienced technicians guidance is available on the phone, and on the internet. One or more engineers will be dispatched to the quarry site to help install the customers’ plants. Necessary training about machine daily maintenance to local workers is provided also.

After-Sales department is made of well-trained employees and installation engineers, the installation engineers are special and professional members of CHAENG, they are now strategically located home and abroad, working for our customers.

The Sand Making Line of our company mainly includes Vibrating Feeder, Jaw Crusher, Cone Crusher (or Impact Crusher), Vertical Shaft Impact Crusher (Sand Maker), Vibrating Screen, Sand Washer, Belt Conveyor, Control System and so on. It can crush limestone and so on.