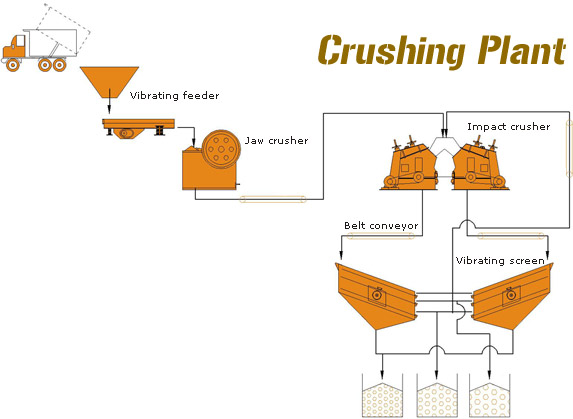

Crushing Plant

Crushing plant includes vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor and centrally electric controlling system, etc. The designed capacity is from 50t/h to 500t/h. To meet customers specific requirement, we can also add other equipments , dust catcher on the production line.

Applications: mining, stone crushing production

Equipment components vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor, focus electric control: Composition equipment

Process description:

Big size limestones are transferred to primary crusher through vibrating feeder from hopper for first crushing, then the crushed materials are transferred to impact crusher through belt conveyor for secondary crushing. The materials crushed will be transferred to the vibrating screen, and separated to different sizes.

The aggregate with suitable size will be transferred to the final product pile and aggregate with unsuitable size will be transferred to the impact crusher forre-crushing. This forms a closed and manifold cycles. The sizes of final products will be graded and separated according to customers' requirements, and the duster will be attached for the sake of environment protection.

Advantage:

We are able to design and manufacture complete crusher plants with capacity from 30tph to 500tph, and to provide optimum and most economical solutions according to customers’ requirements on stone specifications, capacity, application, etc.

1. A complete plant; All the machines are installed on the trailer, saves the occupation space, enhances the working efficiency;

2. Strong flexibility; the mobility is very good, so it can extend with the raw material places or the construction place, and Mobile Crusher(Portable Crusher) can also make multiple matching, get to different product requirements.

3. High efficiency and saving energy.

4. Reliable working, convenient operation, and easy maintenance.

Specification:

| NO. | Equipment | Model | Motor (KW) | Number |

|---|---|---|---|---|

| Hopper | LC3000*4000 | 1 | ||

| Ⅰ | Vribrating Feeder | GZD960*3800 | 11 | 1 |

| Ⅱ | Jaw Crusher | PE600*900 | 75 | 1 |

| Ⅲ | Impact Crusher | PFW1214Ⅲ | 132 | 1 |

| Ⅳ | Vibrating Screen | 3YK1860 | 22 | 1 |

| Belt | ||||

| NO. | Name | Length(m) | Motor (KW) | Number |

| G1 | G800 | 18 | 7.5 | 1 |

| G2 | G800 | 23 | 11 | 1 |

| G3 | G500 | 25 | 7.5 | 1 |

| G4 | G500 | 20 | 5.5 | 3 |

| G5 | G500 | 15 | 5.5 | 1 |

Pre-sales Service:

The wide product range enables us to provide our customers with stand-alone machines or complete processing plants. Based on our customers’ request and budget, our experts make efficient, reliable solutions. Following customers’ order we produce strictly, what’s more, before placing the order every customer has the chance to visit CHAENG working machines or complete plant in the site.

To ease the trip for every visitor to China, in particular the first-time visitor, we provide FOR FREE all relevant visitor-friendly services including invitation letter preparation, hotel reservation, airport pick-up, incity transportation, and sightseeing guide, etc.

After-sales Service:

Experienced technicians guidance is available on the phone, and on the internet. One or more engineers will be dispatched to the quarry site to help install the customers’ plants. Necessary training about machine daily maintenance to local workers is provided also.

After-Sales department is made of well-trained employees and installation engineers, the installation engineers are special and professional members of CHAENG, they are now strategically located home and abroad, working for our customers.

Our company provides a complete crusher plant ,The Crushing Plant mainly consists of Vibrating Feeder, Jaw Crusher, Cone Crusher or Impact Crusher, Vibrating Screen, Belt Conveyors and Control System, etc. The Crusher is applied to multistage crush large materials, and then screen the discharges according to their different specifications.

The whole set plants is widely used to mine, building material, highway, rail way and hydropower industries, etc, It is completely capable to crush and screen limestone, marble, granite, basalt, river stone and so on, and produce sand & gravels with various granularities for construction and building industry.