3000 t/d Cement Plant

| Application | Cement Plant |

| Annual Output | 900,000 tons |

| Process Type | New Dry Process |

| Blaine Fineness | 3300-3800 cm²/g |

CHAENG (Xinxiang Great Wall Machinery) has a history of more than 50 years and has accumulated rich experience in cement machinery. At present, we have been able to supply 500-5000 t/d cement EP project, providing solutions for the world's growing demand for cement.

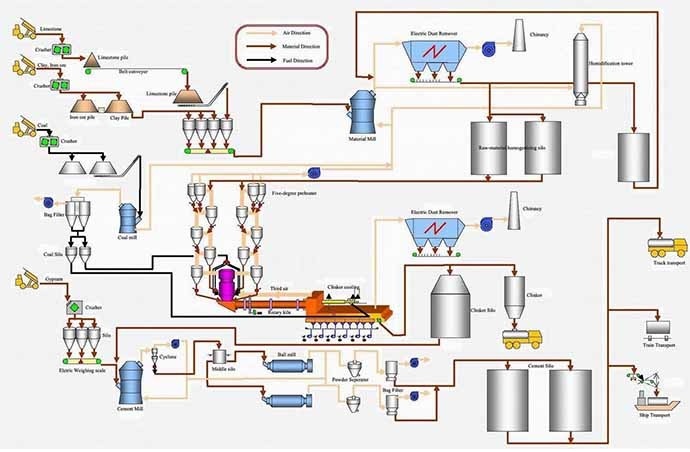

3000 t/d cement production line designed by Great Wall machinery, fully learns from the lessons and experiences of more than 20 years of NSP production line design, the general layout scheme, process layout, equipment selection, automatic control level, etc. and combines with today's international advanced production concept to optimize design. It’s composed of raw materials preparation, raw meal grinding, raw meal homogenization, clinker burning, cement mill grinding, packaging, delivery and so on. The cement equipment in the production line include: raw materials vertical roller mill, vertical coal mill, cement rotary kiln, cement ball mill, cyclone preheater and grate cooler, etc.

3000TPD cement plant process

CHAENG provides turnkey basis service globally with everything that cement plants need We provide service include engineering, manufacturing, procurement, installation, debugging and training for 3000 t d cement plant project The equipment is composed of the low-resistance and high-efficiency five-stage preheating and decomposition system, dry process φ4×60m rotary kiln, inflatable beam grate cooler, advanced vertical roller mill grinding system and DCS automatic control system.

Additive materical’s crushing and storage——Dosing——Limestone‘s crushing and storage——Dusting collecting system——Raw meal homogenizing——Raw mill grinding (Raw mill)——(Coal homogenizing——Coal mill grinding)——Preheating and precalcining system——Rotary kiln calcined (rotary kiln)——Cooler——Clinker storage——Cement Grinding (cement mil)——Additive material crushing——Cement storage——Transportation in bag——Transportation in bulk.

| No. | Product | Model | Specification | QTY | Capacity |

|---|---|---|---|---|---|

| 1 | Single stage hammer crusher |

Feeding size: < 1200x900x900mm product size: < 70mm R95% motor: 600kW |

1 | 400 t/h | |

| 2 | Cantilever stoker | 1 | 500 t/h | ||

| 3 | Bridge-type scraping reclaimer | 1 | 250 t/h | ||

| 4 | Raw Meal Vertical roller mill |

feeding size: < 75mm product fineness: < 12% R90 feeding moisture: max.6.5% product moisture: < 0.5% motor: ~2000kW |

1 | 200 t/h | |

| 5 | Kiln and electric dust collector of raw mill |

Air volume: ~480000m³/h Dust collect area: ~161m² Inlet temperature: 100~150℃ Inlet dust: < 80g/Nm³ Outlet dust: < 70mg/Nm³ |

1set | ||

| 6 | Five-stage Preheater and precalciner |

C1: 2-Φ4500mm C2, C3: Φ6460mm C4, C5: Φ6760mm predecomposition: Φ5060mm differential pressure: < 5500Pa gas temperature of outlet.: 320℃ |

1set | 2500 t/d | |

| 7 | Rotary kiln | Φ4.2x60m |

Kiln pitch: 4% Rotate speed: 0.4~4r/min. motor: 450kW |

1 | 2500 t/d |

| 8 | Grate cooler |

Effective area: ~62.m² clinker temperature of inlet: ~1350℃ clinker temperature of outlet: 65℃ discharging size: < 25mm heat efficiency: > 72% |

1 | ||

| 9 | Electric dust collector of grate cooler |

Air volume: 315000m³/h Dust collect area: ~103.5m² Air temperature of inlet: 220~350℃ Dust content of inlet: < 20g/Nm³ Dust content of outlet: < 70mg/Nm³ |

1 | ||

| 10 | Gypsum crusher |

Feeding size: < 500mm Product fineness:< 25mm motor: 110kW |

1 | 70 t/h | |

| 11 | Cement mill | Φ4.2x12.5m |

Feeding size: < 25mm Product fineness: 3200cm2/g Rotate speed: 15.8r/min. motor: 3000kW |

||

| 12 | Classifier | O-Sepa, N-2500 |

Feeding capacity: max. 360t/h Air volume: 2500m³/min. Motor: 130kW |

80~120 t/h | |

| 13 | Packing in bulk | SZ-2 | Output: ~200(per set) | 4 | |

| 14 | 8 Nozzles Fixed Packing Machine | Output: 100(per set) | 2 |

Our product features:

1.Vertical mill for Raw Material Preparation

Raw material preparation uses GRMR40.41 vertical mill that developed by CHAENG (Xinxiang Great Wall Machinery)GRMR40.41 vertical mill is a kind of grinding equipment with these advantages: simple process, strong drying ability, safe and reliable operation, high grinding efficiency, low power consumption, easy maintenance and short debugging cycle, etc.

2.Clinker burning system with lower energy and heat consumption

This production line adopts advanced raw preheating and precalcining system, reducing the heat consumption and energy consumption effectively in clinker calcined phase. The clinker has better performance, and is easier to grind. Exhaust gases from the preheater enters into the mill, which both saves energy and reduces environmental pollution.

3.Efficient cement mill producing high quality cement

The specific surface of cement produced by cement grinding mill φ4.2×13m is 3300-3800 cm²/g, which meets even beyond the common standard. In the process of using, the cement has the advantage of quick hydration reaction and fast strength development.

4.Good pollution control, greening of factory.

This production line fully considers waste and dust treatment in the design process. We install bag filter and electrical deduster in the main stage of dust treatment, reducing the dust in the air effectively. The whole factory area is fully greening, bringing a good working condition.

Our Services:

CHAENG technical center can help our client to finish feasibility study, environment impact assessment and safety assessment and also provides turnkey service with high efficiency.

CHAENG has its own various processing equipment and takes strict control measures on product quality, which results in fast delivery within a short time. Besides, CHAENG can guarantee completion the project as scheduled with its strong service team for installation and after–sales service.