Hammer crusher

Hammer crusher (hammer mill) is applicable for various hard and fragile materials, such as limestone, coal, salt, gypsum, alum, brick and tile, etc. The crushing compressive strength of materials should not be in excess of 150 Mpa. Hammer crusher is mainly used in industries such as cement, coal separation, electricity generation, building materials etc. And hammer crusher can crush materials with different sizes into equal particle, which favors the next procedure.

Processing ability:5–150 t/h

Feeding size:≤600–≤1200 mm

Applied material:limestone, granite, cobble, dolomite, bluestone, iron ore, construction waste, glass, cement clinker, etc

Process description:

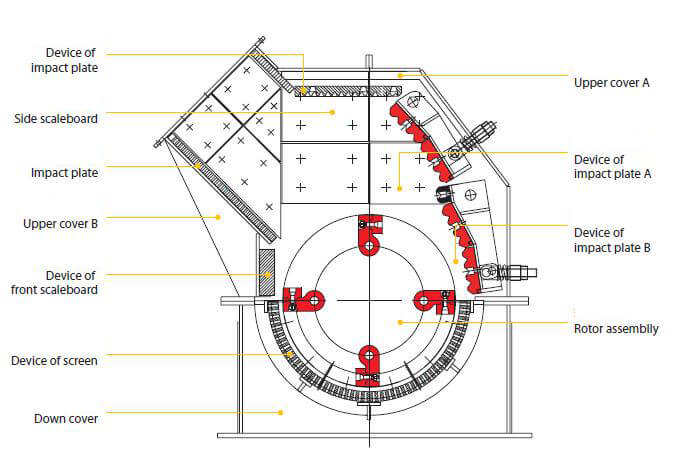

In the hammer mill machine, the motor drives the rotor to rotate at a high speed through the belt, and on the rotor there are series of hammers. When the materials get into the working area of hammers, the rotating hammers with high rotation speed are crushing them; the crushed products meeting the required size can be discharged by the outlet and become the final products; the large size products are brought back to the crushing area by the hammers for being re-crushed until they reach the required size.

Advantage:

1. Big reduction ratio: maximum feeding size is 1.3-1.5m; 3-150mm of discharging size.

2. High fineness of discharging size: favorable shape with aggregate, the powdery material is no more than 20%.

3. Simple process: the two or three stage crushing is reduced into single stage.

4. Economical: small capacity of matched motor, which greatly reduces the production cost.

Specification:

The electric motor drives the rotor and the rotor moves, making the hammer rotate in high speed. The materials are crushed in the crusher by the rotated hammer. The end products come out via the strips of the screen under the machine. The size of the granularity can be adjusted by changing the gap among the screen strips.

| Model | Rotor Length (mm) | Hammer Quantity | Max Feeding (mm) | Capacity (t/h) | Power (Kw) | Machine Size (mm) |

|---|---|---|---|---|---|---|

| GW300*400 | 300 | 16 | <100 | 3-8 | 11 | 855*795*862 |

| GW400*600 | 400 | 20 | <150 | 8-15 | 18.5 | 1155*1100*1255 |

| GW600*800 | 600 | 28 | <220 | 15-30 | 45 | 2360*1500*1580 |

Pre-sales Service:

The wide product range enables us to provide our customers with stand-alone machines or complete processing plants. Based on our customers’ request and budget, our experts make efficient, reliable solutions. Following customers’ order we produce strictly, what’s more, before placing the order every customer has the chance to visit CHAENG working machines or complete plant in the site.

To ease the trip for every visitor to China, in particular the first-time visitor, we provide FOR FREE all relevant visitor-friendly services including invitation letter preparation, hotel reservation, airport pick-up, incity transportation, and sightseeing guide, etc.

After-sales Service:

Experienced technicians guidance is available on the phone, and on the internet. One or more engineers will be dispatched to the quarry site to help install the customers’ plants. Necessary training about machine daily maintenance to local workers is provided also.

After-Sales department is made of well-trained employees and installation engineers, the installation engineers are special and professional members of CHAENG, they are now strategically located home and abroad, working for our customers.

Hammer crusher are applicable for various hard and fragile materials, such as limestone, coal, salt, alum, brick and tile, etc. The crushing compression strength of material should not be in excess of 150Mpa.