Cement ball mill

| Application | Cement Plant |

| Capacity | 21-155 t/h |

| Motor Power | 800-3550 kw |

| Blaine Fineness | 3300-3800 cm²/g |

The cement ball mill is mainly used to grind cement clinker in cement production process, and it also applies to grinding various ores and other grindable materials in industrial and mining enterprises such as metallurgical plant, chemical plant and power plant and so on. Our company has more than 60-year experience on the manufacture of cement ball mill, the quality of our product takes a leading place around the world, providing mature and reliable solutions for many cement production lines at home and abroad.

Working principle:

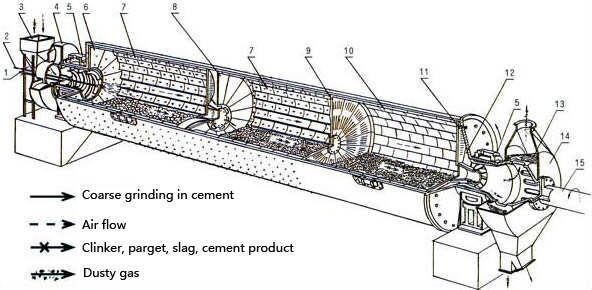

The cement ball mill is composed of horizontal cylinder, hollow shaft and other parts. The cylinder is long round barrel, and there are grinding media in it. The cylinder is made of steel plate, and there is steel liner fixed on the cylinder. The grinding media are usually steel balls, which are placed in the cylinder according to different diameters and certain proportion. The grinding media can also be steel forgings. When the cylinder rotates, due to the centrifugal force, the materials and grinding balls press close to the liner; due to the frictional force, the cylinder send the materials and grinding balls to a certain height; and then due to the gravity, the materials and grinding balls fall simultaneously and the grinding balls crush the materials. Meanwhile, sliding friction generating between the materials and liner grinds the materials, achieving the purpose of grinding the materials.

1. This ball mill, a horizontal type and tubular running device, has two chamber. This machine is grid type. The material enters first warehouse spirally and evenly along the input material hollow axis by input material device.

2. In this chamber, there is a ladder scaleboard or ripple scaleboard, and different specification steel balls. When shell rotates and it produces centrifugal force. At this time, steel balls will be carried to certain height and falls down to make the material heavy impact and grinded.

3. After being grinded coarsely in the first chamber, material enters second chamber for regrinding with the steel ball and scaleboard. At the end, the powder is discharged by output material board and the final products are completed.

Structure characteristics:

- There is high-quality wear-resistant liner in the cylinder. With strong wear resistance, its life time is lengthened effectively.

- The double sliding belt structure is adopted, increasing the stability and running time of the equipment.

- The advanced partition for powder selecting and discharge grate greatly improves the efficiency of grinding and selecting.

- The gap between the bearing cage of sliding belt and the base is sealed with rubber and sealant. While working, the seal is strengthen to prevent the oil from leaking.

Product Advantages:

1. Advanced technology and good continuous behavior in service

Our double sliding belt cylinder mill is the domestic first mill that has fundamentally resolved the difficulty of “cannot run continuously due to overheating of sliding belt axis tile at the discharge end” compared with similar product, which therefore won the national practical new type patent, patent No. ZL201020285841.9. Many examples have demonstrated that the equipment can run steadily and continuously for a long time.

2. The finished product has high fineness and large specific surface

Compared with other enterprises in the same industry, the cement produced by our cement mill has the advantage of high fineness and large specific surface. The cement has excellent quality, high hydration reaction speed, fast strength development, and good intensity after hardening.

3. High efficiency and large output

We have rich experience on the manufacture of cement ball mill, and our technology take a leading place in the industry. Compared with other products in the same industry, the output increases by 15-20%, power consumption reduces by 10%. Moreover, the temperature of finished product can reduce by 10-20℃.

| Model | Output(t/h) | Rotate Speed(r/min) | Grinding Media Load(t) | Effective Volume(m³) | Motor(KW) | Weight(t) |

|---|---|---|---|---|---|---|

| φ2.4*13 | 21-23 | 20.3 | 65 | 51.7 | 800 | 116 |

| φ2.6*13 | 28-32 | 19.61 | 75 | 60 | 800 | 149 |

| φ3.0*13 | 33-37 | 18.08 | 108 | 80.9 | 1250 | 172.3 |

| φ3.2*13 | 45-50 | 17.8 | 128 | 92.4 | 1600 | 218 |

| φ3.2*14 | 48-52 | 18.04 | 138 | 99.8 | 1800 | 228 |

| φ3.5*13 | 55-60 | 17.09 | 160 | 111.2 | 2000 | 250 |

| φ3.8*12 (closed-circuit) | 110 | 16.6 | 175 | 123.6 | 2500 | 203 (excluding drive parts) |

| φ3.8*13 | 66 | 16.4 | 195 | 129.3 | 2500 | 286 |

| φ4.0*13 | 80-85 | 15.5 | 235 | 155 | 2800 | 220 (excluding drive parts) |

| φ4.2*13 (closed-circuit) | 140-155 | 15.6 | 240 | 157 | 3500 | 287 (excluding drive parts) |

Pre-sales Service:

The wide product range enables us to provide our customers with stand-alone machines or complete processing plants. Based on our customers’ request and budget, our experts make efficient, reliable solutions. Following customers’ order we produce strictly, what’s more, before placing the order every customer has the chance to visit CHAENG working machines or complete plant in the site.

To ease the trip for every visitor to China, in particular the first-time visitor, we provide FOR FREE all relevant visitor-friendly services including invitation letter preparation, hotel reservation, airport pick-up, incity transportation, and sightseeing guide, etc.

After-sales Service:

Experienced technicians guidance is available on the phone, and on the internet. One or more engineers will be dispatched to the quarry site to help install the customers’ plants. Necessary training about machine daily maintenance to local workers is provided also.

After-Sales department is made of well-trained employees and installation engineers, the installation engineers are special and professional members of CHAENG, they are now strategically located home and abroad, working for our customers.

Application

Ball mill is a key machine mainly used to process materials from crushing process, and it is widely used in various manufacture industries. It is widely used in Cement Plant, Clinker Grinding Unit, Quicklime Plant, Thermal Power Plant, Steel Mill, Mining etc.

Application case:

1. Deng Electric Group Cement Co., LTD 5000 t/d production line -- Φ4.2×13m cement mill (2 sets)

2. Henan Meng Electric Group Cement Co., LTD(Lingchuan branch) 3200 t/d production line -- Φ4.2×13m cement mill

3. Sichuan Jiahua Co.,LTD 1500t/d cement production line -- 3.0×11m two-cabin cement mill

4. Xinjiang Hetian Luxin Building Materials Co., LTD 1200t/d cement clinker production line -- Φ3.2×13m three-cabin super-fine grinding mill