Three main reasons of choosing CHAENG

Cheap and reasonable price

CHAENG (Xinxiang Great Wall Machinery Co., Ltd.) has near 60-year history and experience of manufacturing large cement equipment, and the equipment manufactured by it has high quality with reasonable price and can meet the construction needs of cement production in different scales.

Customized 300-2500TPD complete cement production line

CHAENG can offer you EPC construction service from design and manufacturing to installation, offer you a suitable plan according to your raw materials and fields, and actually make you free from worry.

The equipment is environmental and durable, and can be maintained conveniently

CHAENG can offer you both main equipment and parts to save delivery time and create more wealth for you.

Technological process

The cement production line is cement plant construction project which is composed of a series of supporting equipment whose function is producing cement.

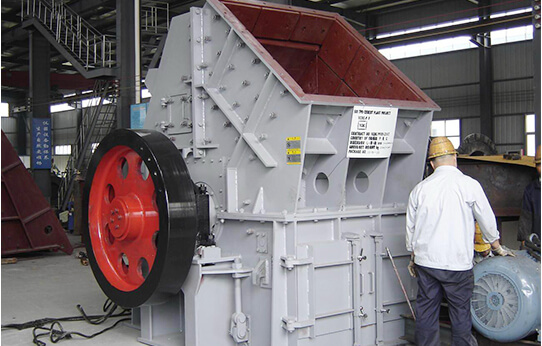

1.Crushing system

Most of raw materials should be crushed, such as limestone, clay, iron ore and so on. The limestone is the main material used in cement production, after mining, the limestone has bigger granularity and high hardness, so the crushing of the limestone occupies an important place in raw material crushing in the cement factory.

We can offer: Online Consultation

Online Consultation

3. Grinding system

This system includes raw material grinding system and cement grinding system, of which cement grinding system is the final process of cement manufacturing and is the most power-hungry process, so selecting proper equipment is the key point to save cost and reduce energy consumption.

We can offer:

Ball mill: advantages: cheap price, using in all over the world, easy operation, convenient maintenance.more >>

Vertical mill: advantages: environmental protection and energy saving, low area occupying, low energy consumption, intelligent control.more >>

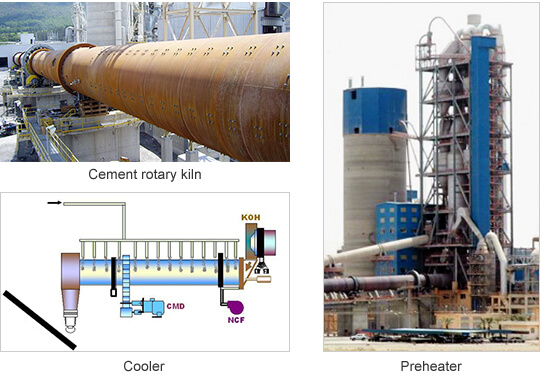

2.Calcination system

After finish the processes of preheating and pre-decomposition, the raw materials enter into the rotary kiln for calcination. In the rotary kiln, the carbonate is further quickly decomposed and starts a series of solid-phase reaction and generates the equal mineral in the cement clinker, and finally, the cooler cools the high-temperature clinker discharged from the rotary kiln to the temperature which can be bore by downstream conveying system, storage depot and cement mill. At the same time the sensible heat of the high-temperature clinker is recycled to improve the heat efficiency of the system and the quality of the clinker.

We can offer: Online Consultation

Online Consultation

4.Packing system

The cement packing machine is a kind of weighting equipment whose functions are sub-packaging the cement and controlling the the weight of a bag of cement to be qualified. Besides it can also be used for filling of other powdery and granular materials with good flowing property.

5.Pulverized coal system and waste gas treatment system

In the process of cement manufacturing, it needs coal, heavy oil or other fuel as heat source, so the manufacturing of pulverized coal becomes an important link. The coal mill manufactured by CHAENG is suitable for grinding soft coal and other materials with medium hardness and used for the pressurized direct pulverizing coal system of burning soft coal. The coal mill not only possesses the advantages of low power consumption, simple coal pulverizing system, small noise and reliable running, but also possesses unique advantages of wide range of material application and good applicability both in high and low load.

We can offer: Online Consultation

Online Consultation

Technical parameters of the production line

Configuration of 1000t/d

| Name of Workshop | Main Equipment |

|---|---|

Limestone crushing & conveying |

Hammer crusher Feed size:≤800×800×800mm Capacity:200t/h Product size: < 50mm for VRM |

| Raw grinding |

Vertical mill Feed size:≦50mm Product fineness: 12 R80 Feed moisture:max.5.0 Product moisture: 1 Capacity:90t/h Power:900kW(decide after test) |

| Coal grinding |

Vertical mill Feed size: 25mm Product fineness: R80um 3% Feed moisture: max.10 Product moisture: 1.5 Capacity: 12t/h Power:280kW(decide after test) |

| Name of Workshop | Main Equipment |

|---|---|

Clinker burning |

Rotary kiln :ф3.2×48m Heat consumption: ≤800kcal/Kg Capacity: 1000t/d Power:160kW(DC) Fuel: coal &petcoke mixture Grate cooler: hydraulic drive Bed area: 30.1m2 Capacity: 1000t/d |

Cement grinding |

Roller pressure:φ1200×500mm Power: 250×2kW Ball mill:ф3.2×13m Product size:320~350m2/kg Capacity:50~55t/h OPC Power: 1600kW |

| Packing machine | Capacity: 100t/h |

Cement grinding plant: simpleness, small investment, high profit

Build cement grinding plant near the cement sales market in the large and middle-sized cities. Most of the cement admixtures are from industrial residue in the city, and the cement grinding plant can vastly digest the industrial residue such as slag, coal ash, furnace slag, coal gangue and so on near the city and is a green and environmental industry.

The technological process adopted by the cement grinding plant is simple, the operation is easy and the investment of process and equipment is small, and the plant is power-saving and environmental and has the advantage of allowing to mix admixtures.

simpleness

simpleness

small investment

small investment

high profit

high profit

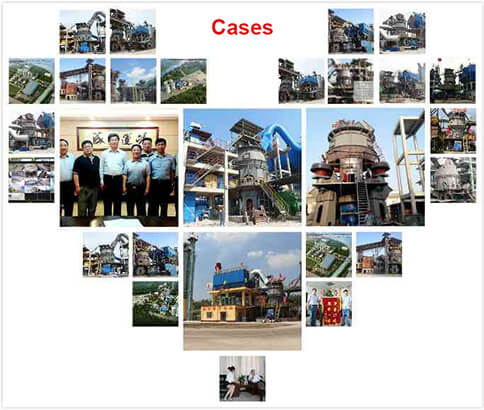

Representative projects of CHAENG

Construction of the cement grinding plant production line with annual production of 1,000,000-1,200,000t ;

construction of the cement clinker grinding plant production line with annual production of 500,000-600,000t;

construction of the cement clinker grinding plant production line with annual production of 200,000-300,000t;

construction of the cement clinker grinding plant production line with annual production of 100,000t.

Technological process

CHAENG offers many services about the cement grinding plant including engineering design, civil construction, whole set equipment, installation and commissioning, technical services and project EPC.

The grinding plant is equipped with high-quality main equipment in grinding system, powder selecting system, dust collecting system and packing system, and the plant finally will make the specific surface area of the cement products reach 320 ㎡/kg. There is no separate admixture drying system, and the plant adopts the mill integrating drying and grinding. The specially designed drying-grinding cement mill completely meets the requirements of the contract, is accepted and successfully goes into operation, and receives many favorable responses from the owners.

Equipment supplied : Ball mill、Vertical mill 、Packing machine

Process advantages

①The cement grinding plant adopts international advanced cement manufacturing technology, and after goes into operation, it will be clean and have high quality, low consumption and high yield.

②The configuration scale of the main equipment is the largest, the quality control measures and equipment are complete, and the quality is stable and reliable and can effectively guarantee the product quality.

③In the manufacturing process, the energy consumption is the lowest and the dust emission is the smallest.

Company strength

Founded in 1958, Great Wall Machinery is the well-known integrated service provider of grinding system, is one of the few old-brand cement equipment enterprises in China, and it has its own research center for slag/cement/lime and other materials, can test clients’ various materials free of charge to study their activity conditions, determine whether they can be used, and provide clients with corresponding technical supports, which indicates that CHAENG is in the front rank in the industry on research of cement, steel and other materials.

In over half-century development, CHAENG bears its social responsibility while pays attention to its own development to promote the social harmony and progress. CHAENG insists to integrate the sustainable development into the manufacturing of the equipment all the time, and establishes management system to implement the sustainable development in CHAENG.

We sincerely hope to serve your cement production!

Our clients

The client from Uzbekistan purchased 1000t/d cement production line

The client from Uzbekistan purchased 1000t/d cement production line

The client from Pakistan purchased cement vertical mill

The client from Pakistan purchased cement vertical mill

The client from Vietnam purchased 3.2×13 m cement ball mill

The client from Vietnam purchased 3.2×13 m cement ball mill

The client from South Africa purchased the supporting roller of cement rotary kiln

The client from South Africa purchased the supporting roller of cement rotary kiln

Online message

| 86-371-55019608 | |

| [email protected] | |

| Mengzhuang Town,Huixian City,Henan Province, China | |

| 86-15515636645 | |

| GreatWall1958 | |

| 86-371-55019608 |