重量:1-300T

材质:普通碳钢、硅锰钢

应用:立式辊磨机

可定制:是的,根据客户的图纸

磨盘是立磨机的关键部件之一,主要由磨盘体、衬板、压块、挡料环、刮料板、风环、导风板等部件组成。长城铸钢优化铸造工艺,采用先进的水玻璃砂造型技术,使磨盘底座受力均匀,增大了磨盘与磨辊的咬合角,避免了磨盘不耐磨表面的侵蚀。

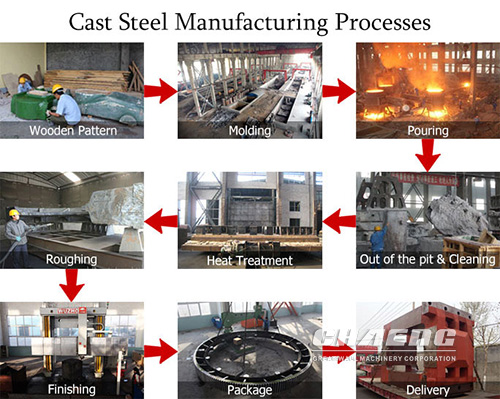

生产流程

长城铸钢根据客户要求,选择合适的木模进行造型设计,在实际铸造前采用CAE模拟铸造,严格按照木模—造型—熔炼浇注—保温—清砂出坑—热处理—粗加工—精加工—包装发货的工艺流程,铸造出高质量的磨台。

1、在铸造工艺基础上优化匹配,采用最先进的水玻璃砂造型工艺,克服了以往结构的不足,使磨盘受力均匀,增大了磨盘与磨辊的咬合角,避免了耐磨表面的刷蚀;

2、先进的加工设备,保证立磨工作台表面光洁度高;

3、出厂前对受力面进行无损检测,确保磨台内外质量符合行业标准;

经过多年的发展,长城铸钢产品已畅销国内各省市,并出口到欧美、德国等多个国家和地区。

图:长城铸钢即将发往乌兹别克斯坦的磨床

图:长城铸钢即将发往印尼的磨床

1.大型铸造基地

长城机械拥有自己的大型铸造基地,并聘请行业顶尖人才作为铸造工艺的高级管理人员和技术骨干,目前长城机械铸造基地已具备为用户提供从铸件到成品的系列服务及关键零部件完整解决方案的综合能力。

2.二次检测,确保配件长久使用

长城铸钢根据客户的不同需求制定具体的工艺方案,严格监控每个铸造环节,确保每件产品出厂前都经过360°无损探伤检测,杜绝所有缺陷产品出厂。先进的技术和一丝不苟的铸造工艺,确保了铸件的质量,使主要备件的首次维修时间比其他产品晚2-3个月。