Grate cooler machine of CHAENG, adopts the new efficient grid plate structure which with very few leakage occurring, less abrasion and longer service life.

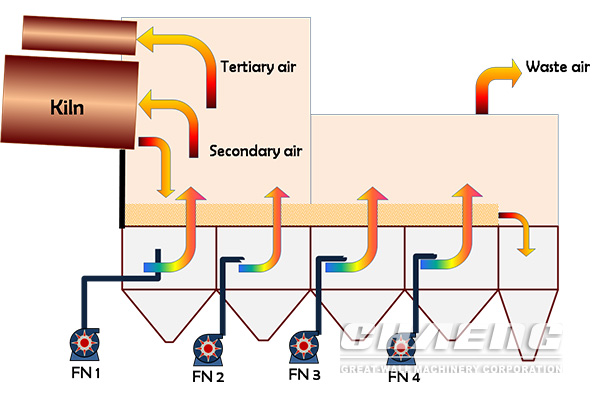

The grate cooler is the main equipment in calcining system of the cement plant. Its main function is to cool and transport the cement clinker. It also provides hot air for rotary kiln and decomposing furnace, and it is the main equipment for heat recovery in calcining system.

Grate cooler of CHAENG is new energy-saving clinker cooling equipment, which adopts international advanced flow-control technology, makes continuous optimization and development relying on advanced thermal technology. Its output can be improved by 20% compared with traditional grate cooler. Heat consumption can be saved more than 10%.

| Model | Output (t/d) | Grate bed effective area (m²) | Unit area capacity (t/ m²) | Drive | Segment |

|---|---|---|---|---|---|

| HCFC-1000 | 1000~1100 | 27.7 | 39.7 | Mechanical | 2 |

| HCFC-1200 | 1200~1300 | 30.5 | 42 6 | Mechanical | 2 |

| HCFC-1500 | 1500~1600 | 36.1 | 44.3 | Mechanical | 2 |

| HCFC-2000 | 2000~2100 | 46.6 | 45 | Mechanical | 2 |

| HCFC-2500 | 2500-2600 | 64.8 | 40.1 | Hydraulic & mechanical | 2 |

| HCFC-3000 | 3000-3200 | 75.8 | 42.2 | Hydraulic & mechanical | 2 |

| HCFC-3500 | 3500-3700 | 87.8 | 42.1 | Hydraulic & mechanical | 2 |

| HCFC-4500 | 4000-4500 | 107.5 | 41.9 | Hydraulic | 2 |

| HCFC-5500 | 5000-5500 | 131.8 | 41.7 | Hydraulic | 3 |

| HCFC-6500 | 6000-6500 | 154.6 | 42 | Hydraulic | 3 |

1. Intelligent control of cooling air volume, energy saving

The optimized grate bed is separated for providing air, and the air volume of each cooling area is controlled accurately to achieve efficient cooling and high heat recovery. The energy saving effect is remarkable.

2. Good wear resistance and easy maintenance

Unique external supporting roller and guide device. The grate bed is support by a separate carrying support roller, which has high surface hardness and good wear resistance. It can effectively prevent the grate bed from sinking, and make the maintenance very convenient.

3. Convenient installation without leakage

4. Long working time

It is made, with a special machining process, by the material of alloy casting steel, which has character of high strength, high temperature resistance and anti-oxidant wear. Thus the machine has high airflow penetration and long service life.

Successful Cases

Photo: Grate Cooler of CHAENG applied in the cement production line of Henan Meng Electric Group

Founded in 1958 and located in Xinxiang, Henan province, CHAENG has 60-year experience in equipment manufacturing with an area of 330,000 m2 and 1 billion RMB of annual production value. The company is specialized in manufacturing all kinds of ball mills, rotary kilns, vertical mills, large steel castings. And we can undertake the EPC projects of cement production line, quick lime production line, blast furnace slag/ steel slag/ nickel slag grinding plants. Its products are sold to more than 50 countries and regions in Southeast Asia, Central Asia, South Asia, North America, South America and Europe.

Our long-term strategic partners: Arcelor Mittal, Tata Group, Pohang Iron and Steel Company, Germany CCE, Japan Chiba , Shanghai Baosteel,Voestalpine and ASGT, etc.

![]()