Capacity: 300-3000 t/d

Cylinder Diameter: Φ3.2-Φ4.8m

Applications: Cement Plants, Clinker Grinding Plants

Applicable Materials: cement, cement brick, refractory materials, clay, bentonite and so on

Cement rotary kiln is used to calcine cement clinker such as limestone and clay to produce cement. The cement rotary kiln produced by Great Wall Company, as the main equipment of dry cement clinker production line, is the most efficient cement calcination equipment and can meet 300-3000 t/d cement production line construction requirements. Cement rotary kiln can also be widely applied in other sectors like metallurgy, chemical engineering, building refractory, environmental protection, etc. CHAENG new dry cement rotary kiln is currently the most reasonable investment in a rotary kiln equipment. Compared with the traditional wet rotary kiln, it is the best for cost saving and pollution reduction in cement production industry in the world.

A cement rotary kiln is mainly formed by rotary kiln shell, girth gear, support roller device, thrust roller support device, kiln lining, kiln tail seal, kiln head hood and fuel plant.

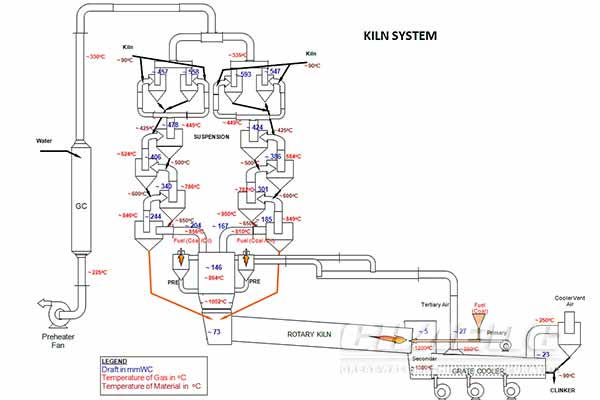

In appearance, the kiln cylinder is inclined to a certain level. The whole kiln shell is supported by supporting roller and equipped with thrust roller to prevent it from moving up and down. In addition to the main drive, the transmission system is also provided with an auxiliary driving device which can still rotate the kiln body and prevent the bending of the kiln body when the in the main power supply is off. The material is fed into the upper end of the air cylinder. As the cement kiln rotates, the materials gradually move towards the lower end, and they may go a certain amount of stirring and mixing. Hot gas goes through the rotary kiln, in the same direction with the processed materials, but usually in the opposite direction. The hot gas may be generated in an external furnace, or may be generated by flames inside the kiln. They are repetitively scattered in the air so that they are in full contact with the hot air, the materials are dried gradually. The kiln head and kiln end adopts advanced sealing technology to ensure the reliability of the seal.

| Model (m) | Kiln pitch(%) | Output (t/d) | Supporting number | Total weight (t) |

|---|---|---|---|---|

| Φ 3.2x50 | 3.5 | 1000 | 3 | 235 |

| Φ 3.3x52 | 3.5 | 1200 | 3 | 280.8 |

| Φ 3.5x54 | 3.5 | 1650 | 3 | 334.2 |

| Φ 4x60 | 3.5 | 2500 | 3 | 487.5 |

| Φ 4.2x60 | 3.5 | 2800 | 3 | 576.1 |

| Φ 4.3x64 | 4 | 3200 | 3 | 585 |

| Φ 4.5x66 | 3.5 | 4000 | 3 | 710.4 |

|

Φ 4.7x72 |

4 | 5000 | 3 | 825 |

| Φ 4.8x72 | 4 | 5000 | 3 | 847 |

| Φ 4.8x74 | 4 | 5000 | 3 | 841 |

| Φ 5x60 | 3.5 | 5500 | 2 | 787 |

| Φ 5.2x61 | 3.5 | 6000 | 2 | 859 |

1. Cement rotary kiln can be used in 300-5000 t/d cement plant

Great Wall Company cement rotary kiln has various specifications such as φ3.2×48m to φ4.8×74m, which can meet the selection and configuration of various output in the market.

2. Advanced technology, easy maintenance

Through technological innovation, the Great Wall Company cement rotary kiln calcination system equipment adopts a new type of hydraulic thrust roller device, as well as high-precision metering plunger pump and speed control valve and contact graphite block sealing device and other technologies, with stable performance, high output, and low consumption.

3. CHAENG provides a full set of cement equipment spare parts

In addition to cement rotary kiln, CHAENG also has various cement equipment and accessories, such as cement vertical mill, cement ball mill, crushers, and various spare parts!

1. Henan Meng Electric Cement Factory purchased CHAENG 5000 t/d cement rotary kiln, with smooth operation, and large yield;

2. Uzbekistan customers purchased cement rotary kiln in the 1000 t/d cement production line!

3. South African customers purchased supporting roller of rotary kiln!