Fineness: 3300-3800 cm²/g

Capacity: 30-250 t/h

Motor Power: 1000-5000kw

Application: Power plant, Cement plant, Lime plant and Steel Plant, etc.

CHAENG, as a professional vertical roller mill manufacturer, has a variety of VRMs for sale, which can be divided into GRMR Vertical Raw mill, GRMS Slag Vertical Mill, GRMK Vertical Cement Mill, and GRMC Vertical Coal Mill according to different grinding materials.

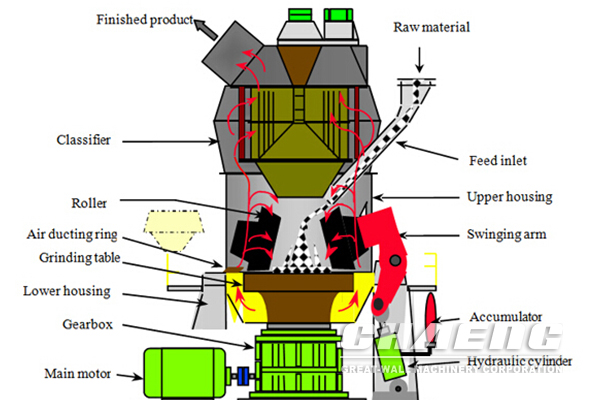

CHAENG GRM series vertical roller grinding mill is mainly composed of separator, grinding roller, rocker arm, grinding table, transmission device, lubricating device, hydraulic pressure device and so on. It has the integrated functions of grinding, drying, powder selecting and conveying, with innovative technologies of high grind efficiency, strong drying ability, low noise, low power consumption and simple process. GRM vertical roller mill is innovative, environmental friendly and efficient, and it has won a number of Chinese technical patents. Especially, The new “one mill, three uses” vertical mill developed in 2015 by CHAENG led Chinese vertical roller mill development to a high peak.

The material through the feed tube fell into the center of the slag vertical roller mill and then the materials outwards the surrounding area of the grinding table at centrifugal force, to form a certain thick layer of materials bed, at the same time, the material was crushed by the vertical mill grinding rollers.

The slag(slag product applications) materials continuous moving to the outer edge of the grinding table, when the material leaves the grinding table and encounters the hot gas entering the mill through the air ring and it will rise into the middle of the separator, in this course materials and hot gas got a fully heat exchange, the water quickly evaporates.

The separator controls the finished product output size, particles larger than the specified size are separated and fall back to the grinding table, and the materials that meet the fineness requirements enter the finished product warehouse through the powder separator.

CHAENG can provide a variety of schemes for cement grinding, and make a choice according to the actual situation and needs of customers:

| Program recommended | Closed-circuit ball mill system | Combined grinding system | Vertical final grinding mill system | |

|---|---|---|---|---|

| Cement types | P·O42.5 | P·O42.5 | P·O42.5 | |

| Cement proportioning ratio(%) | Clinker | 90 | 90 | 90 |

| Limestone | 5 | 5 | 5 | |

| Gypsum | 5 | 5 | 5 | |

| Cement specific surface area (cm²/g) | 3500 | 3500 | 3500 | |

| Capacity (t/h) | 170 | 160 | 160 | |

| System power consumption (KWh/t) | 41 | 33 | 28 | |

| Annual electricity savings (×10,000 Yuan) | — | 400 | 700 | |

| Metal wear (g/t) | 50 (Steel ball) | 30 (Steel ball+Roller surface) | 5 (grinding roller+grinding table) | |

| Dry capacity | Weak | medium | Strong | |

More than 100 customer cases of vertical mill production lines

CHAENG vertical roller mill is applied in many large production lines, playing an important rolls in slag, cement and other material production lines, such as: Shanghai Baosteel 1,500,000 tons /year composite powder (slag, steel slag) production line, Henan Meng Electric Group 1,000,000 tons/year GGBFS production line, Henbei Xinji 600,000 tons/year GGBFS production lines, Xuchang 300,000 tons/year EPC turnkey GGBFS production line, etc.

1. Large output, high efficiency, all parts are manufactured by CHAENG independently.

2. Grinding roller bearings are lubricated circularly with dilute oil, which can ensure the bearings’ work at lower temperature, and moreover the quality and purity of lubricating oil are controlled, conducive to prolonging the service life of bearings;

3. Equipped with roller turning device which can turn the grinding rollers out of the mill, to make maintenance easy;

4. Compared with other types of roller mills, GRM vertical mill hydraulic system has low operation pressure, low oil leakage fault rate and high safety and reliability;

5. The combined-type separator has high powder selection efficiency.

6. Adopts full closed design with little dust pollution.