Ball mill case in Turkey

Purchasing model: φ3.2×6.5m ball mill

Application field: quarry in Turkey

Manufacturer: Xinxiang Great Wall

Customer reviews: We are pleased with our first cooperation that Chaeng (Xinxiang Great Wall Machinery) is very professional and very warm. We hope to cooperate again in mining, steel, cement and other equipment procurement in the future.

Reasons of purchasing ball mill of Chaeng (Great Wall) --Applicable to different mineral grinding work

1. Large capacity, deal with various materials---- Diversifying choices

2. Inexpensive, simple operation--- Low cost

3. Good Grinding quality----- Finished product sales fast

4. Provide spare parts replacement services---- Saving procurement time

cement

cement

material

material

chemical

chemical

slag

slag

Ball mill case in Turkey

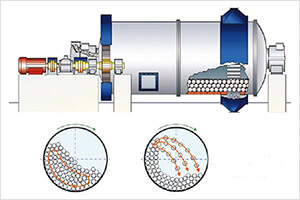

Ball mill Composed by the feeding device, the material device, cylinder, transmission (reducer, small drive gear, motor, electronic control) and other major components. Hollow shaft By the steel casting composition, and the lining is removable, rotary gears using hobbing casting, cylinder body with a wear-resistant liner, it has good wear resistance. Smooth operation and reliable performance.

Working principle

Ball mill is one kind of ore beneficiation equipment, which is mainly used in ore processing operation and commonly seen in ore processing plant. It can grind small pierces of ore into very fine particles, thus preparing for subsequent processing. After being ground by ball mill, ore pulp is formed, then being selected. According to different grinding methods, ball mill can be divided into wet ball mill and dry ball mill. Also, it can be divided into overflow ball mill and grid ball mill according to different discharging methods. By adjusting rotating speed and discharging device, the concentration of ore pulp can be controlled.

Technical advantages

The transmission saves energy

There is drive and grinding energy consumption match,so it can greatly save energy.

The material end design is flexible

The discharge end design is reasonable, the customer can according to their needs to choose and match the iron remover.

Rotary kiln cylinder

Rotary Kiln cylinder, liner, medium, partition plate, the material grate plate are used high-quality original composition.

Feeding a large amount of feed

Reasonable feeding port design, increasing the amount of feed.

Grinding efficiency, liner with good quality

Liners and abrasives using alumina ceramic, quartz, SILEX or special materials, hard minerals with iron pollution-free design.

Using closed system to reduce dust

Ultra-fine ball mill and grading machine to form a closed system, negative pressure transmission, no dust, reduce the harm to human body.Main Spare Parts

hollow shaft

hollow shaft

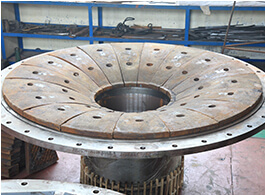

girth gear

girth gear

wearable liners

wearable liners

reducer

reducer

division plate

division plate

bearing bush

bearing bush

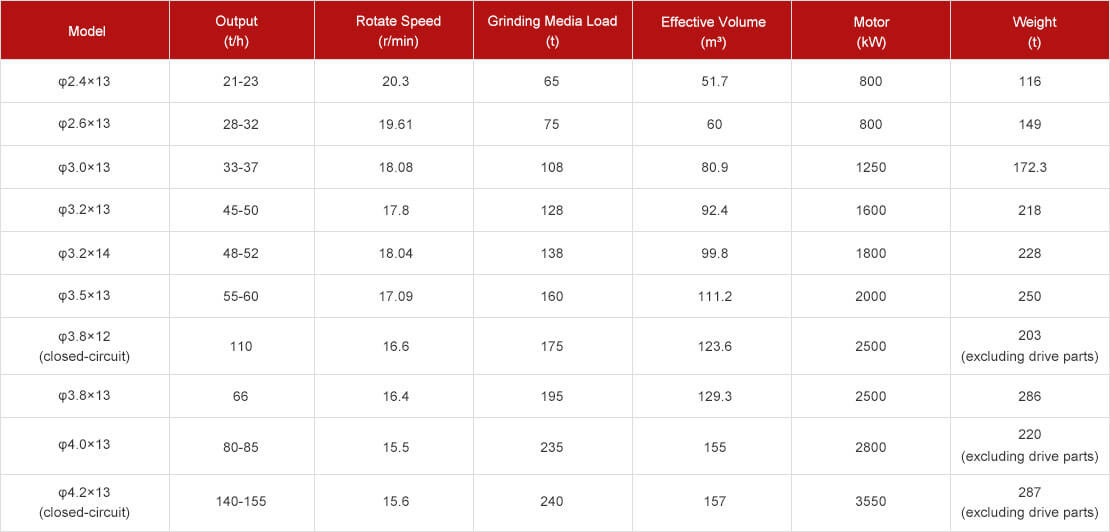

Technical Parameters

Online message

Chaeng (Xinxiang Great Wall Machinery Corporation) was initially built in 1958, located in Xinxiang city, Henan Province, China. It is China's largest grinding system integrated service provider, which has nearly 60 years of large-scale grinding equipment manufacturing and R & D experience, covering an area of 330,000 m² and annual output value of 1 billion Yuan. Development up to now, the company has succeed in supplying more than 100 EPC grinding projects to customers at home and abroad. We produced various ball mill, rotary kiln, vertical roller mill and steel castings and sold all over China and exported to over 50 countries in Central Asia, South Asia, North America, South America and Europe. The global largest vertical roller mills manufacturer Flsmidth and the global largest steelmaker Mittal Group both are our customers.

bearing pedestal

bearing pedestal