30 Aug,2019 UTC+8 Views:

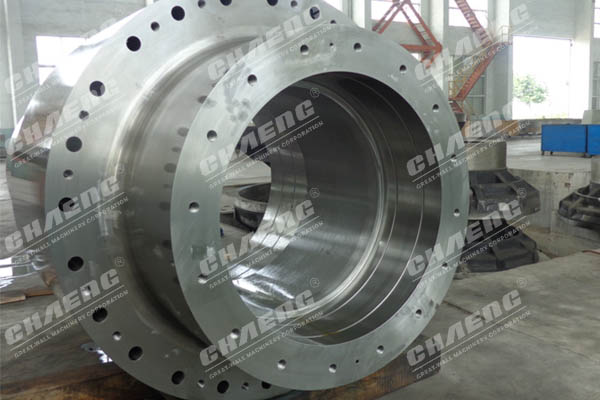

It is known that the vertical mill grinding roller is a key component of the vertical roller mill. Due to the complex composition of the material, often containing some hard impurities, such as stones and iron, it likely to cause severe wear on grinding roller during long-term. CHAENG is able to process various types of grinding rollers.

Grinding roller Process introduction:

CHAENG can customize vertical mill grinding roller according to the drawings provided by the customer, and we can carefully control each step of the casting process:

Before casting, modify the drawings, and simulate the pouring process by computer simulation technology.

In casting, strictly control the size of the molding and the temperature of the molten steel.

After casting, the grinding roller is finished and polished, and the key parts are tested for flaw detection to ensure the overall quality.

CHAENG vertical roller mill grinding roller advantages:

1. The grinding roller of CHAENG has high hardness, good crack resistance and strong wear resistance.

2. CHAENG adopts arc air gouging to finish the grinding rollers, so that the appearance quality of the rollers is guaranteed.

3. The unique design of CHAENG grinding roller makes it has strong wear resistance during operation, so that the maintenance and replacement works are greatly reduced, and the service life is longer.