11 Jun,2018 UTC+8 Views:

With the expansion of the vertical roller mill of the scope of application, the working principle and structure of vertical mill also reminded everyone to explore interest. Chaeng is to help you quickly understand the use of vertical mill .

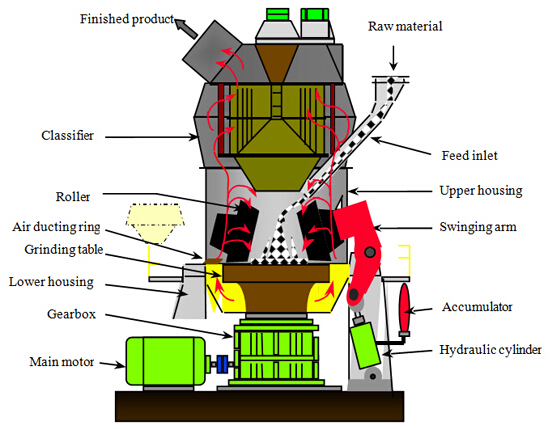

The main structure of vertical roller mill by the separator, grinding roller, grinding table, a pressure device, reducer, motor, shell and other components. The separator is an important part of decision milling product thickness, comprising a driving device, a speed adjustable guide vanes, rotor, casing, coarse powder blanking cone outlet, etc.,it is a kind of powder selecting device, energy saving, fast and efficient. The grinding roller is the main component of rolling grinding of materials, it is loaded in a bent arm grinding machine, under the action of external force, pressed in the disc materials, driven by a millstone, then transferred to the grinding roller, so that the material is compacted and crushing. Grinding table is fixed on the output shaft of the reducer, the upper millstone for bed, with an annular groove material bed, the material is in an annular groove is roll grinding crushed. Provide milling pressure grinding roller component pressurizing device, which is composed of high pressure oil station, hydraulic cylinder rod, an energy accumulator and the like, can exert enough pressure to make the material crushing and grinding roller. The speed reducer is the main power transmission components, grinding disc speed reducer output pumping speed is.

This vertical cement mill is widely used in the grinding of raw materials. It gathers grinding, drying and powder selecting as a whole, with high grinding efficiency and high drying capacity ( the maximum handling material moisture is up to 20% ). The vertical roller mill adopts dynamic powder selecting device, which comes with high powder-selecting efficiency and convenient adjustment of fineness.After crushed by crusher, the large materials become small ones and are sent to storage hopper by elevator, and then evenly sent to the upper distribution plate of the turn plate by vibrating feeder and sloping feeding pipe.The grinding disc is driving by motor through reducer.

The material falls to grinding disc from the feed opening. The materials are driven to the edge of disc by the centrifugal force and crushed into fine powders by rollers. Then, the hot air from the nozzle take the fine powder to high effiency classsifer.

The qualified powder are taken by the air to the powder collector to be collected, while the unqualified powder are sent back for regrinding.

Pre: We need to maintain and replace spare parts in time during rotary kiln shutdown

Next: Chaeng analyzes the factors that affect the life of the big gear