13 Mar,2020 UTC+8 Views:

Steel slag is a waste generated during steelmaking. In order to reduce the environmental pollution of steelmaking plants and ensure that the treatment of steel slag satisfies the principle of “less input, fast output, maximizing the benefits of steel slag, and increasing the amount of recycled steel” Started searching for high-quality steel slag treatment solutions in the market.

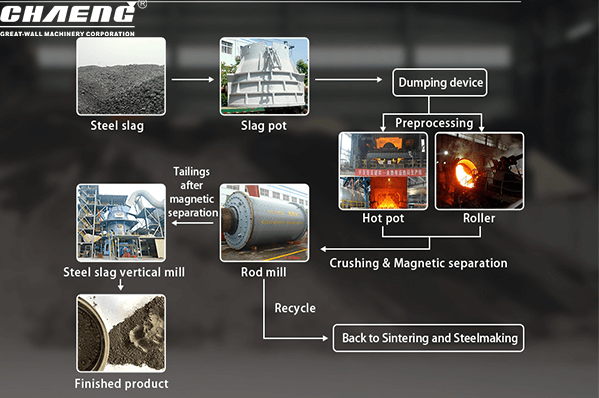

Steel slag processing is generally carried out according to a three-step processing process. The first step is a one-time (hot slag) treatment of steel slag from liquid to solid. The second step is a "smashing-screening-magnetic separation" steel slag secondary processing system. Three-step steel slag grinding can be directly used in the market for concrete and other fields for reuse. The three-step process can completely achieve "zero" emissions of steel slag. In the end, the circular economy goal of reducing, harmless, and recycling the steel slag resources is achieved, and the three unifications of the social, economic, and environmental benefits of the construction project are truly realized.

Chaeng is committed to providing comprehensive solutions for industrial waste slag, conducting comprehensive exploration on the comprehensive treatment of steel slag, and proposing a comprehensive utilization package service plan for the entire process of steel slag, strictly following the three-step treatment process, deducing from "waste" to "Golden Mountain", from the steel "leftover feast" to the resource "feast" of the slag deformation.

The steel slag produced by steelmaking in the steel plant is contained in a slag pot at the slag discharge place. The tilting device holds the slag tank and moves the slag pot. The steel slag is dumped into the drum / hot block pot. The steel slag is processed by the roller / hot block process. Pretreatment to achieve slag-iron separation, while stimulating the stability and activity of steel slag;

The pretreated steel slag is screened by a vibrating feed screen to remove large pieces of slag steel, and then enters the crushing magnetic separation system, and the steel slag is crushed and removed by a rod mill to purify the iron. The purified steel slag tailings have less than 2% metallic iron. The degree is less than 10mm.

The metal materials can be recovered and returned to the iron and steel plant for sintering and steelmaking; steel slags below 5mm enter the grinding system and are ground by the GRMSS series of steel slag vertical mills, which are new and environmentally friendly and efficient. The specific surface area of the steel slag powder produced is 400 -500㎡ / kg. It is widely used in cement and concrete admixtures to achieve high value resource utilization of steel slag.

From the transfer of steel slag raw materials to the pretreatment system, to the crushing and grinding powder, to the product application, once the complete solution of Great Wall's steel slag was launched, it quickly became the focus of attention in the domestic industry, and it was highly recognized by many experts and favored by many customers. At present, it is helping Hebei Ausen Iron and Steel, Xuzhou Iron and Steel and Shanghai Baosteel to achieve "zero emission" of steel slag, which has become a new model for the application of "squeezing and pressing" technology of steel slag at home and abroad, and has played a new movement for green development.

Pre: Rotary kiln shell

Next: Analysis of the cause of the shake of the stone crusher during the operation