27 Nov,2018 UTC+8 Views:

The kiln tyre,it is also known as the rolling ring,which is one of the main components on the rotary kiln equipment. The function of the wheel belt is to transfer the full gravity of the cylinder (including the gravity of the refractory bricks, internal devices and materials) to the supporting wheel, and the cylinder can smoothly rotate on the supporting wheel, so the wheel belt must have sufficient strength and Durability; at the same time, the belt is a part that strengthens the radial rigidity of the cylinder, so sufficient rigidity should be ensured.

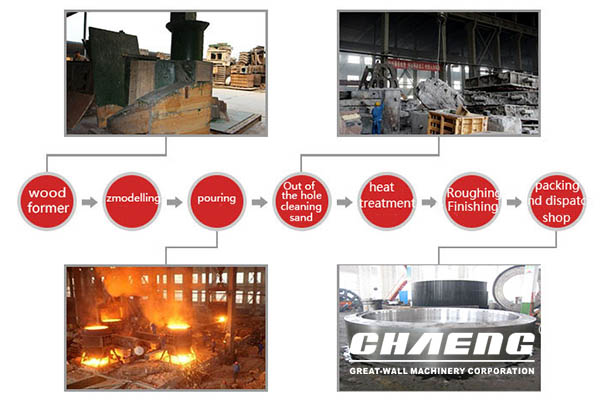

The first step: simulation, modeling

Before casting, the casting process was numerically simulated using Huazhu CAE software, and the process analysis and quality prediction of the product forming process were carried out, and the process of kiln tyre casting was continuously optimized. The metallurgical auxiliary equipment is complete and complete, and the overall size is well controlled. The water glass sand molding process can prevent the occurrence of hot cracks in the castings, and at the same time adopt the pit shape, which is not affected by the season and has high production efficiency.

The second step: pouring, heat treatment

The qualified raw and auxiliary materials shall be put into the electric arc furnace for smelting in proportion, and the molten iron shall be sampled for spectral analysis. After passing the test, the casting shall be carried out according to the principle of “low temperature fast pouring”, and the pouring time and temperature shall be recorded.

The third step: grinding, flaw detection

Finally, cut the riser, flash, etc. Chaeng has a professional polishing and finishing team, large-scale shot peening equipment, which can effectively improve the appearance quality of the kiln tyre, make its surface finish meet customer requirements, and use advanced flaw detection equipment to non-destructively inspect each wheel to ensure internal Quality, strictly eliminate any defective products.

Product advantages

1, the wheel has high strength and good durability

The rotary kiln belts produced by chaeng are made of ZG45 and ZG42CrMO materials, which can ensure the strength and toughness of the belts, thus playing a better role in supporting.

2. The kiln tyre, is treated by advanced double-medium quenching process in the casting process, which is highly adaptable.

The kiln tyre of chaeng is treated by advanced double-medium quenching process, and each part is forged uniformly. It has the characteristics of high quenching hardness and high toughness value, which makes the wheel belt have good wear resistance and can adapt to various harsh working environments. .

3, the kiln tyre structure is simple, easy to process manufacturing and daily maintenance.