21 Nov,2018 UTC+8 Views:

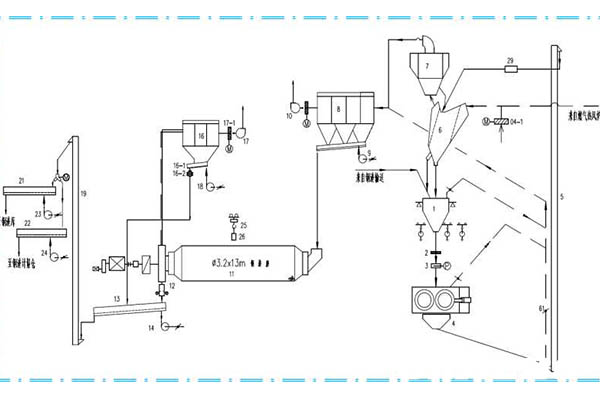

The design of the 300,000 tons steel slag powder production line of Ninggang follows the principle of advanced technology, mature technology, convenient operation and reasonable economics. It is guided by the production of stable and reliable, energy-saving and environmental protection.

In order to achieve the “zero” emission of steel slag and the promotion and application of high added value of steel slag powder products, according to the actual situation of the site, according to the compact arrangement and smooth flow, the land can be used efficiently; strictly in accordance with the state's environmental protection, labor safety, industrial hygiene, Designing standards and standards for measurement, fire protection, etc., to ensure that environmental protection and economic benefits are both up to standard.

1) Converter steel slag, after crushing and removing iron, treated to a particle size of <10mm, iron content <2% (the external cycle selects the iron content of 1.87%, the iron content of the finished steel slag powder is 0.3%. It is required to reach the iron content < 1%), moisture 7% to 10%.

2) GRM42.21 steel slag vertical grinding, the main motor power is 1900Kw. The thickness of the running layer is 25~30mm, the height of the retaining ring is ≤140mm, the loading pressure is ≤10Mpa, the vertical grinding operation is stable, and the horizontal and vertical vibration values are all about 1.1~1.2. The motor power of the powder separator is 160Kw, and the actual use is 45%~49%.

3) Steel slag powder specific surface area 430m2 / kg (45μm sieve residue 10 or less, 80μm sieve residue 1.0 or less), designed to produce 50 tons, the actual production of 60 tons or so, up to 70t / h, the production with wear roller wear Will slowly reduce, down to about 45t / h should stop the surfacing. The external displacement during the operation process is <30%.

4) The operating system has a minimum power consumption of 42Kwh/t, and the wear of the grinding roller is 50 degrees and above. Coal consumption calorific value 4200Kcal coal consumption of about 20kg. Original grinding roller and liner grinding 130,000 tons, wear 10g / t; external third-party surfacing repair wire 1.3t, grinding more than 80,000 tons, wear 16g / t; external third-party re-welding welding wire 1.3t, observe and contrast when grinding 25,000 tons, the wear condition is normal.

Pre: How to distinguish cast steel from cast iron in our life

Next: Rocker arm and five slag pots ship to nanjing,Italy after the factory celebration