23 Apr,2018 UTC+8 Views:

In order to meet the increasingly stringent environmental protection requirements of the industry,chaeng upholds the concept of sustainable development, continuously upgrades the ore slag powder line program, and strives to build a more energy-saving and environmentally-friendly slag production line total package program, winning customers' favor and recognition.

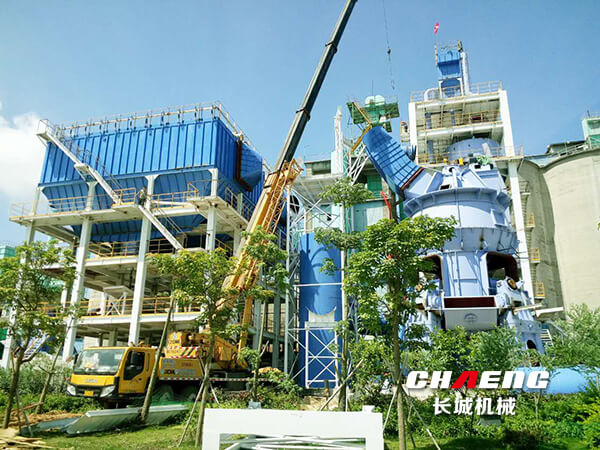

The slag powder line host adopts energy saving and environmental protection vertical roller mill

The vertical mill system operates in a closed-circuit circulation system without dust pollution. The gas discharged by the induced draft fan is a clean gas that meets the requirements of environmental protection;

Vertical roller grinding machine adopts advanced grinding method, which can save 30%-40% energy consumption compared with ball mill, not only reduce production costs, but also help reduce air pollution, and achieve a win-win result of economic benefits and environmental protection benefits.

The heat source of the slag production line can be adopt clean fuel

The slag powder production line can use relatively clean fuels such as natural gas, blast furnace gas and biofuels as the heat source, which can reduce air pollution and achieve economic and environmental benefits.

Slag stacker fully enclosed design

The raw material yard, chaneg slag Powder Line adopts a totally enclosed environmental protection design, which can isolate dust pollution inside the greenhouse and reduce the pollution to the environment.

Waste residue, waste gas and waste water produced during production meet discharge standards

The slag powder Line water production line is used for cooling water circulation, and the domestic water evolved septic tanks form no flow (not to be discharged); the solid wastes of the slag powder line are dust, and the dust points at the belt blanking points and the conveyor belts are collected to ensure dust collection. Environmental requirements, and dust collected as a product for sale.

In the future,chaeng will continue to respond positively to the call for environmental protection, take the responsibility for the mission of sustainable development bravely, continue to implement the concept of environmental protection in the new form into the mine powder line project, and take the green, low-carbon and cyclic sustainable development path for the construction. Beautiful China contributes a force.