09 Apr,2018 UTC+8 Views:

Recently, in Hebei, a well-known steel base, another 300,000 tons slag production line that was constructed by chaeng, which was formally put into operation and will supply high-quality slag powder for local and surrounding infrastructure construction.

The Hebei customers who cooperated with chaeng utilized the abundant local slag resources and invested in the slag micro powder project. The ball mill grinding process was used to produce the ore slag fines. With the increase of national environmental protection efforts, in May 2017, Hebei customers cooperated with chaeng to build a production line of 300,000 tons of slag powder per year. The mill was used to produce slag powders to reduce energy consumption and environmental protection costs. National environmental protection requirements, improve the economic efficiency of enterprises.

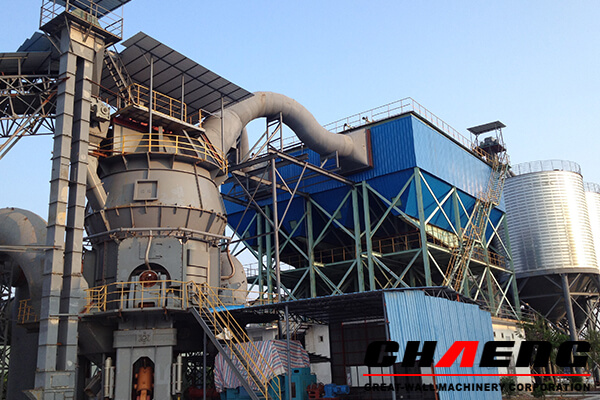

According to the requirements of Hebei customers,chaeng has equipped GRMS33.31 slag vertical mill with energy saving and environmental protection features for the annual production capacity of 300,000 tons of slag powder production line. GRMS33.31 slag vertical mill integrates crushing, drying, grinding, powder selection and transportation into one, advanced technology, high grinding efficiency, low energy consumption, low noise, small dust pollution, and gas discharged by the induced draft fan is The clean gas that meets the environmental protection requirements has greatly reduced the environmental pollution.

After commissioning, the energy consumption of the production line is low, the feeding capacity is 55 t/h, the output is 47 tons/hour, the finished product specific surface area is 420 square meters/kg, the equipment is operating normally, and the production reaches the standard. It meets the national environmental protection requirements and meets customer requirements.

From single-unit equipment supply to one-stop “turnkey” services, chaeng is committed to providing customers with tailor-made EPC general contracting services, designing industrial waste residue grinding processes and processes according to customers' special requirements, and satisfying customers' individualization. Demand to help customers achieve business transformation and increase economic efficiency.