1. Magnetic Separator

The magnetic separator is a device that produces strong magnetic fields to attract magnetic material. It is commonly used to remove unwanted ferrous contaminants such as iron from feedstock mixtures as they are conveyed on a belt conveyor to the crusher and grinding mill. This avoids the risk of long, big iron parts tearing open the conveyor belt, ensures the proper functioning of the crusher and grinder, and improves the grade of raw material. Additionally, recovering ferrous metals from raw materials also comes with financial benefits.

Our permanent magnet separator for pipeline is a high-performing, automatic magnetic separation device. It is widely used in cement, electricity, ceramics, bricks and tiles, chemical engineering, food, glass, metallurgy, and steel industries. This device is a separator of choice when it comes to purifying materials and ensuring the operational safety of the downstream equipment on the production line.

2. Dust Collector

Air-borne powder, which has been finely ground and dried, enter the rotary separator at its bottom, where guide vanes force the air to change from an upward flow to a tangential flow. The separator rotor tends to rotate along with the air flow without causing any resistance. Therefore, a centrifugal zone is formed between the guide vanes and separator vanes. In that zone, powder is separated from air.

During separation, larger particles are thrown outward by rotary force of the separator rotor, striking the outside wall of the separator and falling to the bottom once again due to the force of gravity. After exiting the centrifugal zone, these oversize particles are collected in a conical hopper and returned to the roller mill for further grinding. Finer particles are brought through the center of the separator chamber and out the top, where they are collected by a dust collector.

3. Central Control System

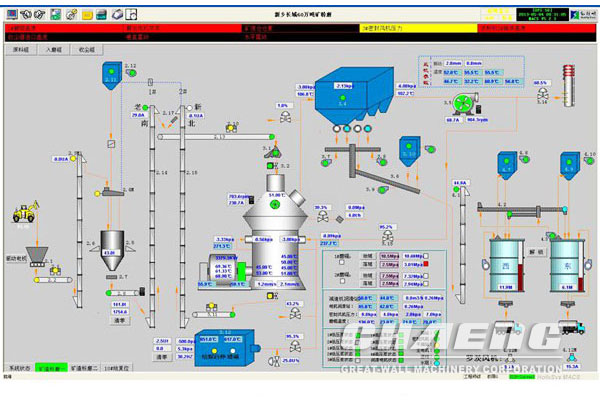

The central control system is a critical part on the slag grinding plant. It is made up of the Distributed Control System, and the Closed-Circuit Television which contains 6 monitor circuits.

In a distributed control system, or DCS for short, there are a number of computers, each controlling a separate circuit. Information from each computer can be collected together and obtained by the central controller, which facilitates centralized management and control. Compared with the computer controlled multilevel system, DCS has the advantages of optimized, flexible layout, low cost, high reliability, maximum accessibility, great flexibility, easy maintenance, good compatibility, and comprehensive functionalities.

The closed-circuit television, or CCTV, records images of different production sites, stores them in a hard drive, and sends real-time information to the control center. Authorized staff can view the present state of each production site. In case of emergency, they are able to send men to the site. This prevents potential severe accidents from occurring. Typical functions of CCTV include the following.

1. Multiple monitor circuits

2. Video recording

3. Video search

4. Video replay

5. Pan control

6. Camera lens control

Ever since the project was put into use, it has brought in considerable profits as sales of slag powder are still on the increase. 3 years of smooth operation has seen full cost recovery. Huge profits are expected in the fourth year. Even more beneficial, this project demonstrates our manufacturing ability. After customers visit our project, they gradually learn to rely on our products and services. Enhanced trust of customers allows us to win more construction bids.

Main Equipment:GRMS46.41 Vertical Roller Mill for Slag Powder

Production Ability:600,000 tons of slag powder per year

Founded in 1958 and located in Xinxiang, Henan province, CHAENG has 60-year experience in equipment manufacturing with an area of 330,000 m2 and 1 billion RMB of annual production value. The company is specialized in manufacturing all kinds of ball mills, rotary kilns, vertical mills, large steel castings. And we can undertake the EPC projects of cement production line, quick lime production line, blast furnace slag/ steel slag/ nickel slag grinding plants. Its products are sold to more than 50 countries and regions in Southeast Asia, Central Asia, South Asia, North America, South America and Europe.

Our long-term strategic partners: Arcelor Mittal, Tata Group, Pohang Iron and Steel Company, Germany CCE, Japan Chiba , Shanghai Baosteel,Voestalpine and ASGT, etc.