Output: 200,000-1,500,000t/a

Specific surface area: 420~500m²/kg

System power consumption: ≤38 Kwh/t

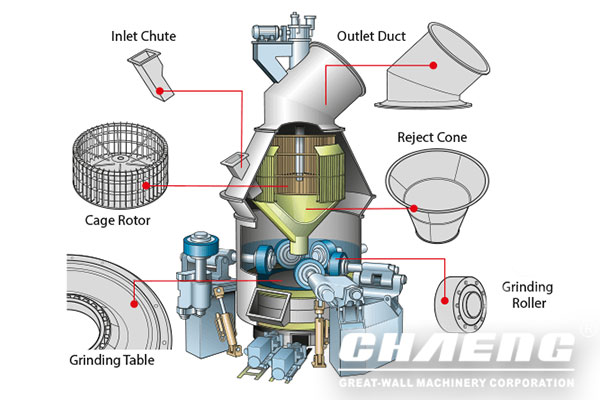

The materials fall to the center of the grinding table through the blanking pipe, then the grinding table is rotating at a constant speed and disperses and spreads out the materials evenly with the aid of centrifugal force, which makes the grinding table become the material bed with a certain thickness. Then several grinding rollers on the grinding table grind and crush the materials at the same time. With the continuous centrifugal force, the materials constantly move toward the outer edge of the grinding table. When the materials that leave the grinding table meet the hot gas which enters the mill through the wind ring, the materials will also rise. Then the materials enter into the separator through the mill’s middle shell, during this process, the materials and the hot gas have sufficient heat exchange with each other, and the water is quickly evaporated. The powder separator controls the size of the finished products, particles that are larger than the specified size will be separated and fall back into the grinding table, and particles that meet the fineness requirement will enter the finished products warehouse through the powder separator.

| Model | Grinding Table Diameter(mm) | Number of grinding rollers | Motor(kw) | Output(t/h) |

|---|---|---|---|---|

| GRMS33.31 | 3300 | 3 | 1600 | 45 |

| GRMS35.41 | 3500 | 4 | 1800 | 60 |

| GRMS40.41 | 4000 | 4 | 2240 | 70 |

| GRMS43.41 | 4300 | 4 | 2800 | 90 |

| GRMS46.41 | 4600 | 4 | 3150 | 105 |

| GRMS48.41 | 4800 | 4 | 3550 | 125 |

| GRMS50.41 | 5000 | 4 | 3800 | 140 |

| GRMS53.41 | 5300 | 4 | 4200 | 150 |

| GRMS56.61 | 5600 | 6 | 5000 | 160 |

1. Indonesia Nickel Slag Vertical Mill GRMS33.31 Vertical Mill

2. 2×GRMS33.31 nickel slag vertical mill in Xuchang

1. The specific surface area of nickel slag micro powder can reach 480-500㎡/kg, which ensures the activity of nickel slag can be exerted.

The material stays in the body for a short time, and it is easy to detect and control the particle size and chemical composition of the product, and reduce repeated grinding.

2. Reduce energy consumption by 30%, low noise, energy-saving and environmental protection

Compared with the ordinary ball mill, the nickel slag vertical mill can reduce the energy consumption by 30%, and at the same time, the noise is low. The vertical mill adopts the internal negative pressure system, which effectively reduces the overflow of dust, and responds to the national policy call for energy conservation and emission reduction.

3. Short supply cycle to ensure product quality

Xinxiang Great Wall Machinery has its own large steel casting base, machining workshop, electrical workshop, the main components of vertical mills, such as grinding discs, grinding rollers, rocker arms, etc., from casting to finished products, auxiliary machines such as dust collectors, oil Stations, electrical control cabinets, non-standard pipes, etc. are all self-made by the company, which not only ensures the processing quality and progress of the whole set of equipment, but also solves the problem of difficult maintenance of various equipment by customers in the later stage.