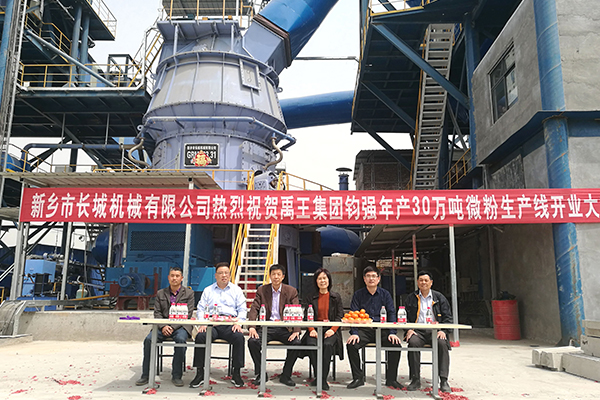

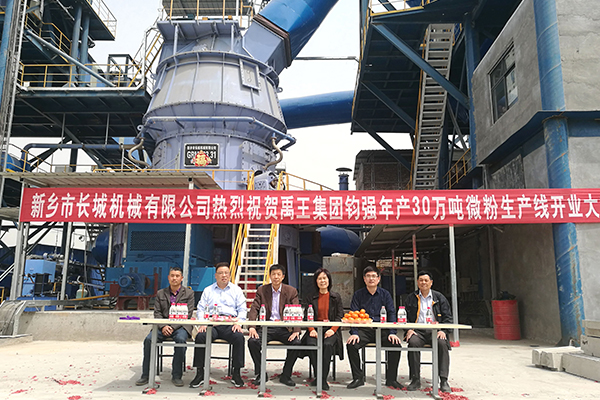

The GRMR raw material vertical mill of CHAENG is a kind of new high efficiency, energy saving and environment friendly grinding equipment specially for cement raw material grinding system in cement plant. Its output can reach 720 t/h, power consumption is 17~20 kWh/t. It has the advantages of high grinding efficiency, low power consumption, low noise, and little dust pollution, can meet the requirements of 300-10,000 TPD cement production line.

Mill exit temperature too low

Potential causes:

False air

Damper positions

Proposed solutions:

Reduce damper between conditioning tower and filter

Reduce damper of re-circulation air flow

Expected results:

Less humidity in mill product

Lower temperature in filter

Estimated costs:

Minimal

Implementation time:

Short-term

Roller pressure too low

Potential causes:

High vibrations

Pressure adjustment does not follow wear

Proposed solutions:

Train mill operators

Adjust pressure periodically

Expected results:

Increased feed rate and higher production

Reduced specific power consumption

Estimated costs:

Minimal

Implementation time:

Short-term

Air speed variations in mill

Potential causes:

Cone design

Inclination of nozzles

Proposed solutions:

Redesign cone

Adjust inclination of nozzles (35 ° to 60 °)

Expected results:

More uniform speed increase

Less material falling through nozzle ring

Reduced specific power consumption

Estimated costs:

Minimal

Implementation time: Mid-term